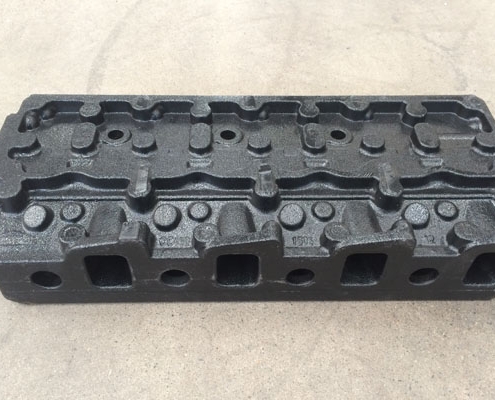

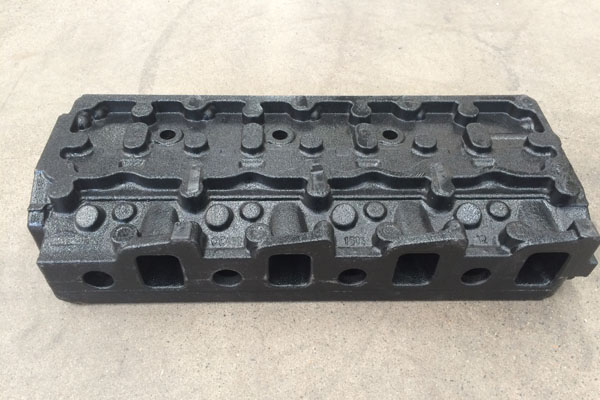

Sand mold casting

what is sand casting?

Sand casting is a widely used form of casting. As the name suggests, sand is used to make molds. Sand casting requires placing a finished part model or a wooden model (pattern) in the sand, then filling the pattern around the sand, and unpacking the pattern to form the mold.

In order to remove the mold before casting the metal, the mold should be made into two or more sections; during the mold making process, holes and vent holes for casting metal into the mold must be left to synthesize the casting system. The casting mold is poured with the metal liquid for a suitable period of time until the metal solidifies. After the parts are removed, the mold is destroyed, so a new mold must be made for each casting. Sand mold processing plants can cast large parts. Sand molds can be used for iron casting, bronze casting, brass casting and aluminum casting. Wet casting is another sand casting process that is inexpensive and can produce parts of various sizes.

Sand mold casting characteristics

Permeability

When the metal solution is poured into the sand mold, the high temperature of the molten metal evaporates the moisture in the mold sand into a gas. If the mold sand has good gas permeability and allows these gases to escape smoothly, the casting can avoid the occurrence of defects such as pores.

Strength

When the molten metal flows into the sand mold, the sand mold is heated to dry, and the bonding strength of the sand at this time also needs to be resistant to the easy flushing and pressure of the gold metal.

Refractoriness

Mould sand should retain its original physical and chemical properties at high temperatures without deformation or melting.

Fineness

In order to obtain a casting having a good surface smoothness, the molding sand needs to have a suitable fine density to prevent the molten metal from infiltrating into the molding sand to form a poor casting surface.

Collapsibility

The mold sand has good collapsibility, which makes it easier to clean the casting and recover the sand.

Sand mold casting and metal casting difference

Sand mold casting is a kind of casting method using sand as the main molding material, which is generally carried out by gravity casting. However, if there are special requirements, low pressure casting, centrifugal casting, etc. can also be used. As a whole, the adaptability of sand casting is very wide. Sand casting can be used for large and small parts, simple parts, complicated parts, etc. In addition, it can be mass-produced. However, it also has the disadvantage that each mold can only be poured once, so the production efficiency is not high. The castings obtained are not dimensionally accurate and have a rough surface.

Metal mold casting is different from sand mold casting because it uses heat-resistant alloy steel, and its mold can be used repeatedly without damage, so it can greatly improve production efficiency. Moreover, for castings, dimensional accuracy and surface roughness can be greatly improved. Hangzhou gravity casting machinery, therefore, metal casting is preferred when conditions permit. However, its disadvantage is that the cost is not low.

Sand mold casting process

Sand casting can greatly improve industrial production efficiency, provide technology for the future development of industrial production, science and technology develop rapidly, and integrate new technologies into the design and manufacturing process of modern sand casting molds. The board model increases certain accuracy. Effectively accelerate the production speed in the production process and promote the stable and rapid development of industrial production technology.

Sand casting

Most of the material resources used in sand casting are cheap raw materials. The materials used to manufacture parts in industrial production often use wood, gypsum and gas pipes, and are widely used in the models required for production. Casting models are often not adapted to the manufacturing model in production. In order to effectively integrate the two, the cast model can be applied to industrial production. The important basis of the sand casting procedure is the sand casting mold. The industrial production technology of the society is continuously improved, and it is widely used in various fields, which can greatly improve the overall quality of industrial raw products.

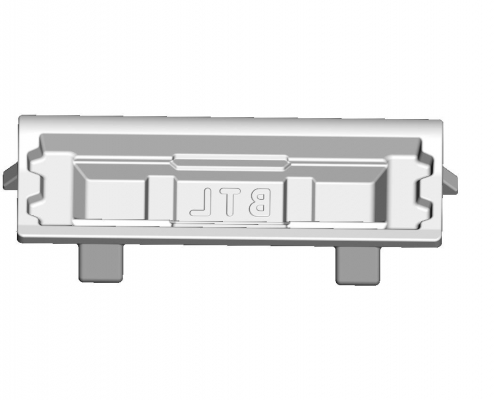

Mold design for sand casting

(1)setting the plane design

The sand casting mold is affected by the precision of the sand casting mold design. By accurately designing the sand casting mold model, the corresponding sand casting mold steps can be refined. When reviewing the plan design of the sand casting mold, it is necessary to accurately measure the data of each step of the flat design, and accurately draw the main view, the top view and the left view of the mold design. In the actual design process, the three-dimensional characteristics of the sand casting mold application need to be briefly described. For the data required in the model design, such as radius, length, width and height, it is necessary to accurately determine the specific data. In this way, the mold design data can be guaranteed to be within a certain accuracy range. When designing the sand casting mold, the design staff needs to set a certain change space value for the relevant data, and then perform data verification according to the applied data model, so as to ensure the design data of the sand casting mold. accuracy. Sand molds are initially set up prior to design and are effectively compared for design values for length, width, height and radius. When the dynamic space is reserved for the data, the needs of the sand casting mold design will be considered, and the accuracy of the design data of the killing casting mold will be further improved.

(2) Establish a data model for sand casting mold

The sand casting mold plane design is the second step in the sand casting mold design. By calculating the sand mold casting model, the data of the sand casting mold plane design can be effectively determined. Some data models used in sand casting mold design require different calculation modes, which also involve many function calculation modes, and preliminary data setting for the dependent variable Y and the independent variable X. In the design process of the sand casting mold, it is necessary to accurately analyze the data and analyze the relationship between the independent variable and the dependent variable, so that the functional relationship between the independent variable and the dependent variable can be profoundly Research, on the whole, can guarantee the accuracy of the data applied in sand casting mold design.

(3)design mode stereo processing

The third step in the design of sand casting mold is to carry out three-dimensional processing on the sand casting mold design image. In the process of image stereo processing of sand casting mold, the traditional sand casting mold design and modern sand casting mold design are fully integrated. It can also apply more advanced computer virtual communication technology. The computer virtual composition technology can make a three-dimensional combination of the plan of the sand casting mold design. Through the fusion of the technologies, the numerical values of the sand casting mold design can be effectively controlled, through continuous data control and refinement steps. Finally, a sand casting mold design model was formed. In the process of designing the sand casting mold, it can be integrated into the virtual computer network, and the virtual computer network can carry out corresponding operation specifications on the graphics of the casting mold design. In the process of actual operation, various problems will be encountered, and the corresponding problems of the virtual simulation production need to be corrected and analyzed, so that the intelligent management of the current sand casting mold design can be strengthened as a whole.

(4)Complete sand casting mold design

The fourth step in the design of sand casting mold is to complete the graphic design of the corresponding mold. In the process of overall rationalization and scientific processing of the flat pattern, the virtual three-dimensional technology can be fully integrated into the sand casting mold design. Through a series of data processing and graphic processing, the corresponding design drawings can be manufactured and improved accordingly. Referring to some data in the sand casting mold process, combined with the corresponding sand casting mold design technology, the corresponding actual operations can be continuously performed. perfect. In the process of the sand casting mold, it is necessary to summarize the problems in time for the existing problems, and then seek the best solution to solve the corresponding problems.

Manufacture of sand casting molds

In the process of designing sand casting molds, the production technology often used is the corresponding mold design technology, which can greatly improve the corresponding production efficiency and ensure the production quality of sand casting molds as a whole. According to the corresponding sand casting mold design drawing, the corresponding mold related technology can be effectively planned to ensure the quality and efficiency of the overall production. By systematically inputting the initially set data, it is possible to effectively mass-produce sand casting molds and promote the development of China’s technology as a whole. The RP technology can be used for modern mass production of sand casting molds, and the overall analysis and differentiation of sand casting mold production technology can be effectively carried out to ensure that the sand casting mold can be improved in quality in the production process. In the design process of the sand casting mold, it is necessary to ensure the accuracy of the application data of the sand casting mold design as a whole, and fully integrate the traditional sand casting mold design and the modern sand casting mold design. The use of modern technology can enhance the control of sand casting molds as a whole, ensure the production quality of sand casting molds, and ensure that modern production techniques can be effectively utilized in the overall manual inspection.

Common problems in the process of sand casting

Stomata

There is a hole-like defect in the casting, and the inner wall is generally smooth and has a slight oxidation color. Once the casting has pores, it will affect its impact resistance and fatigue resistance. In addition, the air holes can also reduce the compactness of the casting and even scrap the casting.

Sand eye

It is similar to the air hole, and it can be inside or on the surface of the casting. Its influence on the casting is also very large. However, we can avoid some problems, such as increasing the sand strength and rationally designing the casting structure.

Sticky sand

It is to attach a layer of sand that is difficult to remove on the surface of the casting, which will affect the appearance quality of the casting and increase the workload, so it cannot be ignored. However, this problem can be avoided if pulverized coal is added to the molding sand or if the anti-stick coating is applied to the surface of the mold.

Cold isolation and insufficient pouring

When there is a cold separation, there will be seams on the casting that are not fully fused, which will seriously affect the mechanical properties of the casting. Insufficient pouring will result in the casting not being able to obtain a complete shape.