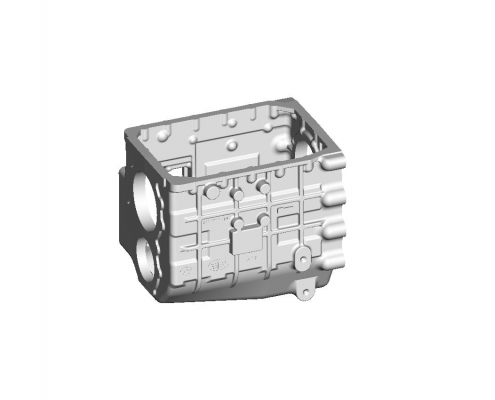

Automotive gearbox mold

The shape of the car gearbox housing is quite varied, so I will change and innovate in the exterior structure and manufacturing. Using UG drawing, 3D modeling and analysis, external surface modeling optimization and manufacturing feasibility analysis, to achieve the manufacturing requirements of the exterior design; the gearbox housing is punched and formed during manufacturing. The designed gearbox housing has the advantages of beautiful appearance, easy loading and unloading, low production cost, large batch size, stable quality and high production efficiency.

| Place of Origin: Henan, China (Mainland) | Brand Name: Liushi&OEM | Model Number: Customized |

| Product Name: Automotive gearbox mold | Material: Aluminum | Surface treatment: TEFLON surface coating |

| Service:

Customer’s Drawings |

Certification: ISO9001 | Dimensions: Customized Sizes |

| Application:

Machinery Parts |

Process: Lost Foam Casting | Lead Time: 45 Days |

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

|

Mould material

|

ZL106 aluminium casting alloy,7075 reflectal

|

|

Casting alloy

|

Cast aluminium,Cast steel,Grey iron,Ductile iron

|

|

Cavity qty

|

Single cavity, Multiple cavity, Unit cavity

|

|

Process

|

Adopts CNC, WEDM-LS, drill machine, polishing machines, lathe, milling machine,etc.

|

|

Treatment

|

TEFLON surface coating treatment and Heat treatment and etc

|

|

Design software

|

AutoCAD, UG, Pro-E, Solidworks, etc

|

|

Lead time

|

15to 30 days for samples, exact time depends on mold complexity

|

|

Forming machine

|

Cold chamber die-casting machineS180T/280T/500T/800T/1250T

Hot chamber die-casting machines58T/88T168T

|

|

Mold life

|

30000 to 50000 depend on products

|