https://www.ls-casting-mold.com/wp-content/uploads/2023/09/反击破2.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 11:17:582024-05-17 11:17:58Complete list of hammer crusher models

https://www.ls-casting-mold.com/wp-content/uploads/2023/09/反击破2.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 11:08:532024-05-17 11:08:53How does an impact crusher work?

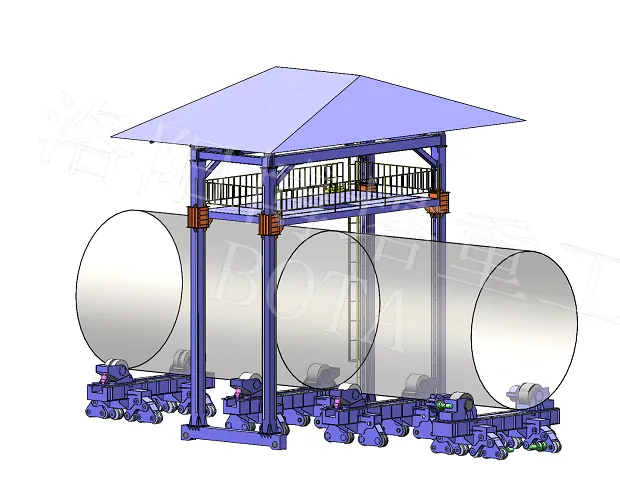

https://www.ls-casting-mold.com/wp-content/uploads/2023/11/1.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 11:02:262024-05-17 11:02:26What is the production process of wind tower welding production line?

https://www.ls-casting-mold.com/wp-content/uploads/2024/05/Gantry-CNC-Cutting-Machine.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:57:062024-05-17 10:57:06What parts does a gantry CNC cutting machine consist of?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/20.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:43:012024-05-17 10:43:01How does the vibrating screen work?

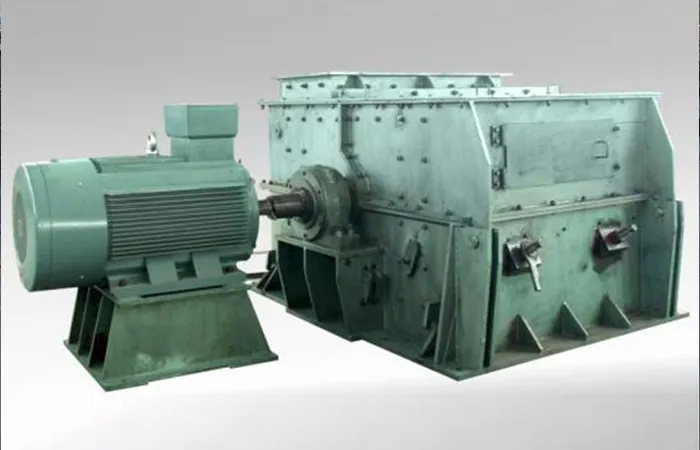

https://www.ls-casting-mold.com/wp-content/uploads/2024/05/46.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:32:102024-05-17 10:32:10How does a vibrating feeder work?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:19:592024-05-17 10:19:59What systems does a glass tempering furnace consist of?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:09:362024-05-17 10:09:36What are the features of glass tempering furnace?

https://www.ls-casting-mold.com/wp-content/uploads/2024/05/steel-office-cupboard.png

800

800

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 10:02:072024-05-17 10:02:07What is a steel instrument cabinet ?

https://www.ls-casting-mold.com/wp-content/uploads/2024/05/未标题-1.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-05-17 09:55:512024-05-17 09:55:51What are the functions of gun cabinets?

Scroll to top