https://www.ls-casting-mold.com/wp-content/uploads/2023/03/plate-conveyor-已有.jpg

400

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-15 13:52:022023-03-15 13:52:02What are the types of conveyors

https://www.ls-casting-mold.com/wp-content/uploads/2022/02/Concrete-mixer-truck(1)-e1645164067497.jpg

378

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-09 11:30:462023-03-09 11:30:46How to calculate the capacity of concrete mixer truck

https://www.ls-casting-mold.com/wp-content/uploads/2022/08/forging-process.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-09 11:16:362023-03-09 11:16:36WHAT IS THE PRODUCTION PROCESS OF RING FORGINGS

https://www.ls-casting-mold.com/wp-content/uploads/2022/05/PU20.02602.jpg

700

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-09 10:53:492023-03-09 10:53:49Which industries are cross roller bearings used in?

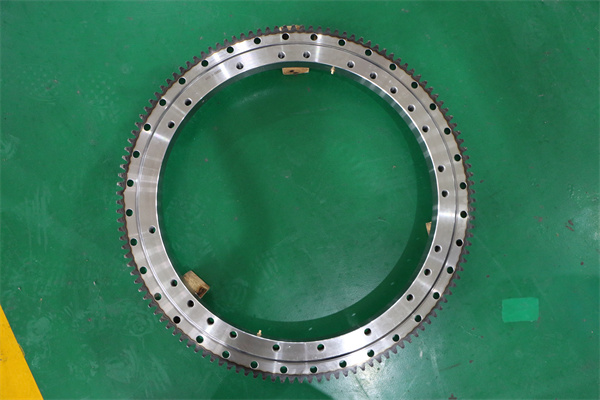

https://www.ls-casting-mold.com/wp-content/uploads/2022/06/IMG_6351.jpg

400

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-09 10:30:072023-03-09 10:30:07Why do you need to replace the excavator slewing bearing and how to replace it

https://www.ls-casting-mold.com/wp-content/uploads/2022/02/954-e1645597921663.jpg

400

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-09 10:18:092023-03-09 10:18:09How to choose a tractor clutch supplier

https://www.ls-casting-mold.com/wp-content/uploads/2022/02/12-e1645582658515.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-08 13:53:362023-03-08 13:53:36What are the characteristics of the grow racks with lights?

https://www.ls-casting-mold.com/wp-content/uploads/2022/02/糊底机全图-e1644893738778.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-08 10:52:232023-03-08 10:52:23What is the process of making paper tubes

https://www.ls-casting-mold.com/wp-content/uploads/2022/03/calcium-hydroxide.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-08 10:34:352023-03-08 10:34:35HIGH SPECIFIC SURFACE CALCIUM HYDROXIDE PRODUCTION PROCESS

https://www.ls-casting-mold.com/wp-content/uploads/2022/02/Vibrating-Screen4-1.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2023-03-08 10:02:352023-03-08 10:02:35What are the performance advantages of a single deck horizontal screen

Scroll to top