Алюминиевый лист cladding has become a preferred choice for modern commercial and residential buildings. Сочетание легкости и прочности, устойчивость к коррозии, эстетическая универсальность делает его идеальным для создания визуально ярких и долговечных наружных стен.. Однако, achieving the full benefits of aluminium cladding depends heavily on proper installation. This comprehensive guide provides practical steps, tips, and industry best practices to ensure a flawless facade that stands the test of time.

Aluminium Sheet Cladding Installation Guide for Exterior Walls

1. Planning and Material Selection

Proper planning is the foundation of a successful aluminium cladding project. Ключевые соображения включают в себя:

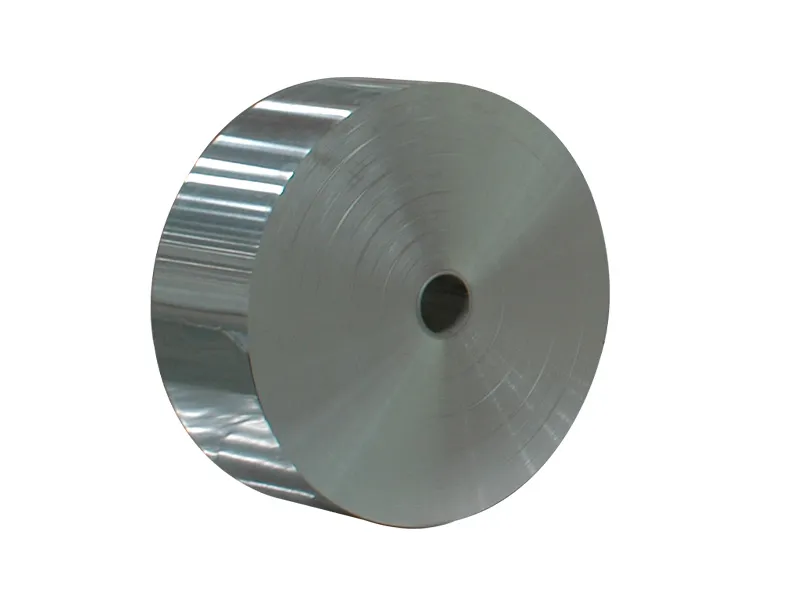

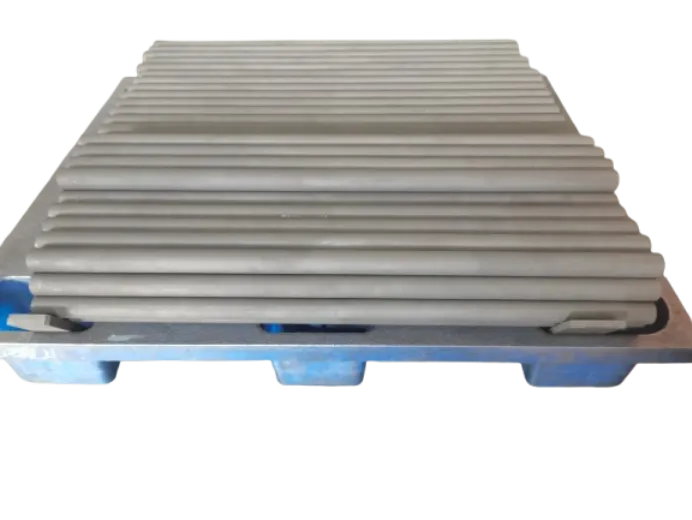

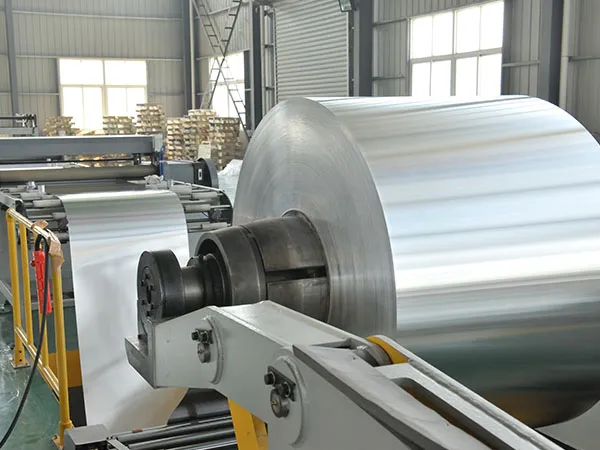

Type of Aluminium Sheets: Select from plain, perforated, or composite panels based on design, ventilation needs, и воздействие погоды. Композитные панели могут обладать дополнительными изоляционными свойствами..

Толщина и отделка: Для наружных стен, Панели обычно имеют толщину от 2 мм до 4 мм.. Порошковое покрытие или анодирование повышают долговечность и сохраняют постоянство цвета с течением времени..

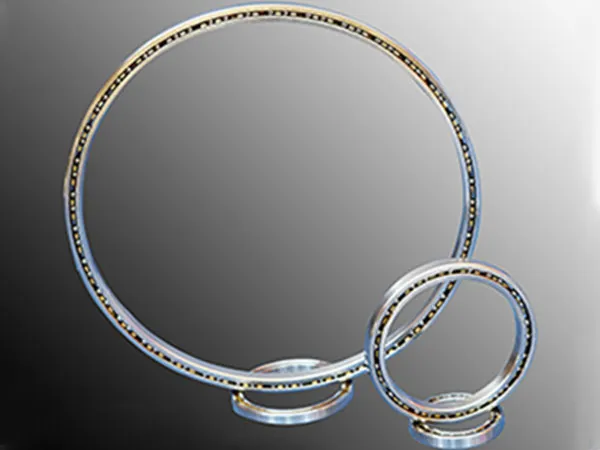

Структура поддержки: Убедитесь, что подрамник (алюминий или нержавеющая сталь) может выдержать вес панели, выдерживать ветровые нагрузки, и противостоять коррозии.

Время, потраченное на планирование, сокращает затраты на последующие корректировки и обеспечивает структурную стабильность на десятилетия..

2. Подготовка поверхности стены

Хорошо подготовленная поверхность стены обеспечивает надежное крепление и выравнивание.:

Уборка: Удалить пыль, обломки, жир, или влага, чтобы предотвратить проблемы с адгезией.

Выравнивание: Исправьте неровные поверхности штукатуркой или выравнивающими составами, чтобы избежать короблений и зазоров..

…

Для получения более подробной информации об установке наружных стен из алюминиевых панелей., пожалуйста, нажмите, чтобы посетить: https://www.dw-al.com/a/news/aluminium-sheet-cladding-installation-for-exterior-walls.html