Hornos de templado de vidrio are essential in the glass manufacturing industry, enabling the production of tempered glass, which is significantly stronger than regular annealed glass. This article explores the technical aspects of glass tempering furnaces, including their design, operación, tipos, and maintenance.

Principles of Glass Tempering

Glass tempering involves heating glass to a temperature just below its melting point (approximately 600-650°C) and then rapidly cooling it. This process induces compressive stresses on the surface and tensile stresses inside, resulting in increased strength and improved safety characteristics. Tempered glass shatters into small, blunt pieces rather than sharp shards.

Components of a Glass Tempering Furnace

Heating Section

Elementos de calentamiento: Typically made from high-resistance alloys such as Kanthal (FeCrAl) or Nickel-Chromium (NiCr) alloys. These elements provide consistent and uniform heating.

Insulation: High-quality refractory materials like ceramic fiber boards or alumina-silicate bricks are used to insulate the furnace, reducing heat loss and improving energy efficiency.

Control de temperatura: Advanced control systems, often employing thermocouples and infrared sensors, ensure precise temperature regulation throughout the heating chamber.

Quenching Section

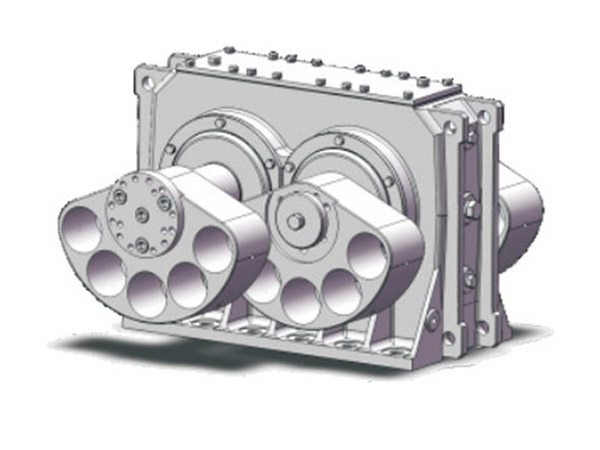

Air Blowers: Powerful fans generate high-pressure air streams for rapid cooling. The airflow must be uniform and controllable to achieve the desired stress profile in the glass.

Nozzles: Specially designed nozzles distribute air evenly across the glass surface. The nozzle arrangement and size are critical for achieving uniform cooling.

Sistema de transporte

Rodillos: Heat-resistant rollers, often made from fused silica or ceramic-coated steel, transport the glass through the furnace. The roller speed is adjustable to control the heating and cooling rates.

Mecanismo de manejo: Precision motors and drives ensure smooth and consistent movement of glass through the furnace.

Types of Glass Tempering Furnaces

Horizontal Tempering Furnaces

Operación: Glass moves horizontally through the furnace on rollers.

Aplicaciones: Suitable for flat glass panels used in windows, doors, and automotive applications.

ventajas: Reduced risk of glass surface damage and higher throughput.

…

For more detailed information about the introduction of glass tempering furnace e, por favor haga clic para visitar: https://www.shencglass.com/en/a/news/what-is-a-glass-tempering-furnace.html