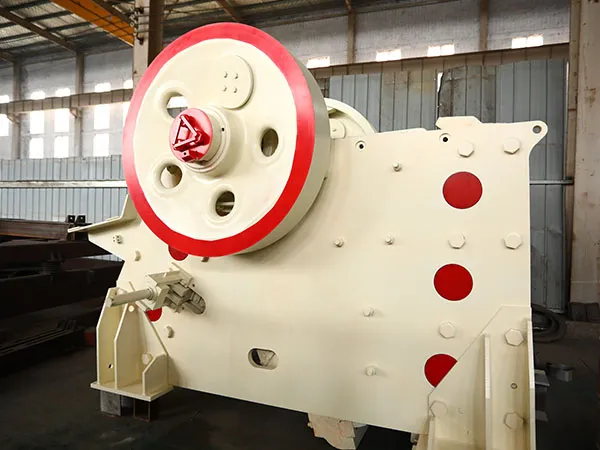

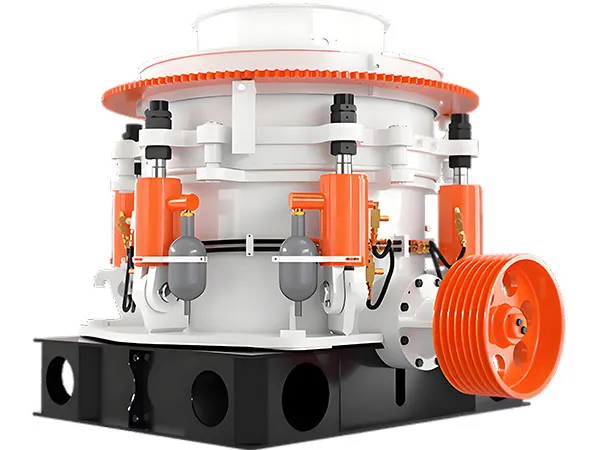

trituradoras de cono son ampliamente utilizados en la minería, cantera, y producción de agregados para reducir rocas grandes en más pequeñas., tamaños uniformes. Sin embargo, debido a operaciones de trituración continuas bajo carga pesada y condiciones abrasivas, piezas de desgaste críticas como mantos, cóncavo, revestimientos, y los revestimientos de los tazones experimentan un desgaste gradual. El reemplazo oportuno de las piezas de desgaste de la trituradora de cono es esencial no solo para mantener una alta eficiencia de trituración y un tamaño constante del producto., sino también para extender la vida útil general del equipo y reducir el tiempo de inactividad no planificado.

Reemplazo de piezas de desgaste de una trituradora de cono, principalmente el manto y cóncavo (revestimiento del tazón), Es un proceso de varios pasos que requiere atención cuidadosa a las pautas de seguridad y del fabricante.. Estas piezas suelen estar hechas de acero con alto contenido de manganeso debido a su durabilidad y resistencia al desgaste..

Reemplazo de piezas de desgaste de trituradora de cono

Seguridad ante todo!

Bloquear/Etiquetar: Antes de iniciar cualquier mantenimiento, Asegúrese siempre de que la alimentación de la trituradora esté desconectada y bloqueada para evitar un arranque accidental..

Equipo de protección personal (EPP): Use EPP apropiado, incluyendo casco, lentes de seguridad, guantes, y botas con punta de acero.

Leer el manual: Consulte siempre el manual de operación y mantenimiento de su trituradora específica para obtener instrucciones detalladas y procedimientos de seguridad..

Pasos para reemplazar piezas de desgaste

1. Preparación y Desmontaje:

Limpiar la trituradora: Asegúrese de que la trituradora esté vacía de cualquier material..

Retire la carcasa superior (si es aplicable): Dependiendo del modelo de su trituradora, Es posible que tengas que quitar la carcasa superior para acceder a algunas piezas de desgaste.. Por lo general, esto implica desatornillarlo y levantarlo con cuidado con el equipo de elevación adecuado..

Retire el tazón (Cóncavos/Manto):

Afloje las tuercas del tazón: Utilice una herramienta especializada o una llave de impacto para aflojar las tuercas grandes que sujetan el revestimiento del tazón. (cóncavo) en su lugar.

Levante el tazón: Utilice una grúa u otro dispositivo de elevación para levantar y retirar con cuidado el recipiente..

Eliminar cóncavos viejos: Una vez que el tazón está apagado, los viejos cóncavos se pueden desatornillar o sacar. A menudo están respaldados con epoxi o zinc., que habrá que romper.

2. Reemplazo del manto:

El manto es la pieza de desgaste de la cabeza del cono..

…

Puede encontrar información más detallada sobre cómo reemplazar las piezas de desgaste de la trituradora de cono en: https://www.yd-crusher.com/a/news/cone-crusher-wear-parts-replacement.html