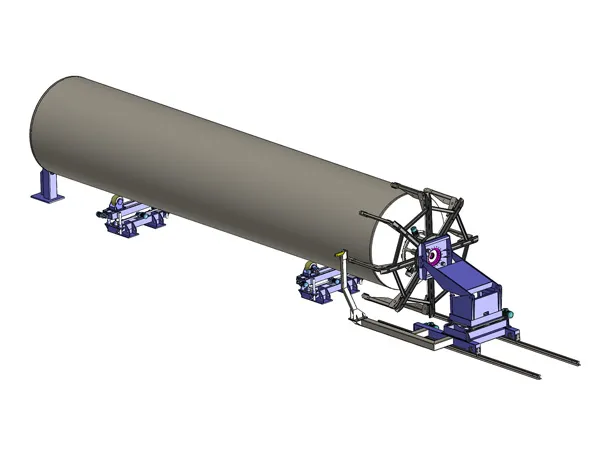

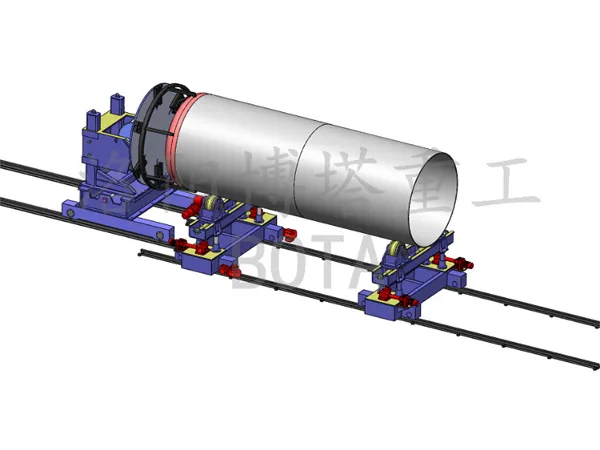

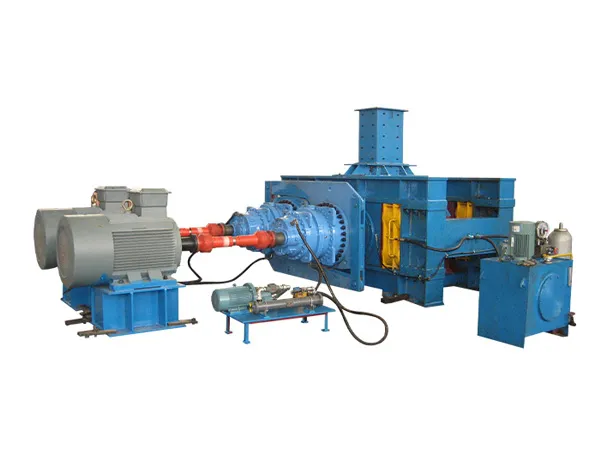

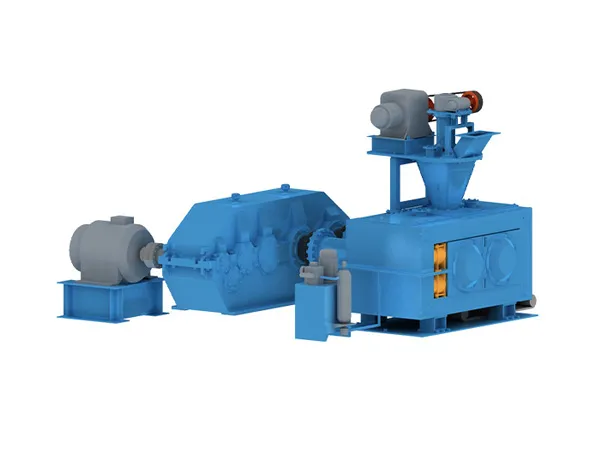

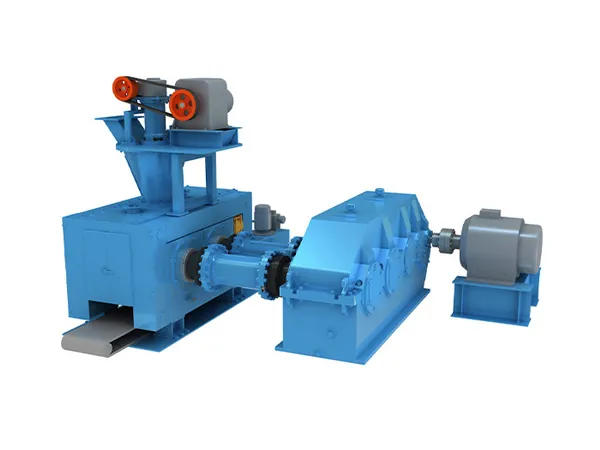

Circumferential seam welding machine is an important automatic welding equipment, which is mainly used to complete the welding of various circular and annular seams.The circular seam welding machine is based on the principle of ordinary arc welding. It uses argon to protect the metal welding material. Through a large current, the welding material is melted into a liquid state on the welded substrate to form a molten pool, so that the welded metal and the welding material can achieve metallurgical bonding. Due to the continuous supply of argon during high-temperature melting welding, the welding material will not come into contact with oxygen in the air, thereby preventing the welding material from being oxidized. Por lo tanto, stainless steel and ferrous metals can be welded.

Circumferential seam welding machine operating procedures

The operating procedures of the girth welding machine are important guidelines for ensuring that the welding process is safe, efficient and high-quality. The following are the operating procedures of the girth welding machine compiled from multiple sources:

1. Preparation before operation

Be familiar with the equipment:

The operator should be familiar with the basic structure, working principle and operating procedures of the girth welding machine.

Understand the meaning of the various functions, control buttons and indicator lights of the equipment.

Inspect the equipment:

Check whether the power cord and switch are normal, and ensure that there is no debris on the machine body and around it.

Check whether the relevant grounding wires and grounding devices of the welding equipment are reliable.

Check whether the cables, welding guns and welding parts are intact and there is no leakage or short circuit.

Prepare materials:

Confirm whether the required welding materials, herramientas, equipo, protective supplies, etc. are prepared in sufficient quantities.

Check whether the welding materials meet the requirements, including material, specifications, dimensiones, etc.

Clear welding requirements:

Confirm the material, espesor, specifications, process and other requirements of the welding workpiece.

Select appropriate welding parameters and welding methods according to welding requirements.

…

For more detailed information on the operating procedures of the circumferential seam welding machine, por favor haga clic aquí: https://www.bota-weld.com/en/a/news/circumferential-seam-welding-machine-operating-procedures.html