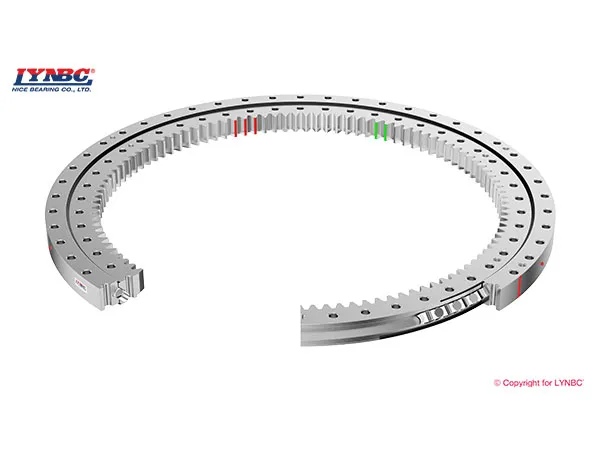

Slewing bearings are critical components in large equipment like cranes, excavators, and wind turbines, enabling rotation and supporting significant loads. A robust replacement strategy is essential to minimize downtime, ensure safety, and optimize operational costs. This strategy involves a combination of proactive maintenance, condition monitoring, and a well-planned replacement or repair process.

Slewing Bearing Replacement Strategy for Large Equipment

I. Proactive Maintenance and Inspection (Preventive & Predictive)

The goal is to extend bearing life and predict failure before it happens.

Regular Lubrication:

Frequency: Follow manufacturer guidelines. This typically ranges from every 50-100 hours of operation for slow-moving equipment to every 8 hours for continuously rotating equipment.

Method: Add grease slowly while rotating the bearing to ensure even distribution and purge old, contaminated grease. Sufficient grease is applied when it overflows from the seal.

Type of Grease: Use heavy-duty, extreme-pressure (EP) grease as recommended by the manufacturer.

Gear Lubrication: If the slewing bearing has integrated gears, lubricate them separately as their requirements differ from the raceways. Apply small amounts of grease at the point of mesh.

Bolt Torque Checks:

Initial Check: After 100 hours of initial operation, re-check bolt torque.

Subsequent Checks: Every 300-500 hours, and more frequently in harsh conditions (vibration, shock).

Procedure: Wipe bolts clean, apply thread-locking adhesive if replacing, and tighten to the manufacturer’s specified pre-tension (often 70% of the bolt material’s yield limit). Use Q&T (quenched and tempered) washers; spring washers are prohibited.

Importance: Loose bolts can lead to uneven load distribution, localized stress, and premature failure.

Visual Inspections:

Frequency: At least weekly, or before each operation.

What to look for:

Cracks or damage on the slewing ring.

Signs of biting, gnawing, or surface peeling on gear teeth.

Integrity of seals: replace damaged seals promptly and reset any that have fallen off. Seals prevent contamination of the raceways.

Unusual noise or impact during rotation.

…

For more detailed information on large equipment slewing bearing replacement strategies click to visit: https://www.lynicebearings.com/a/blog/slewing-bearing-replacement.html