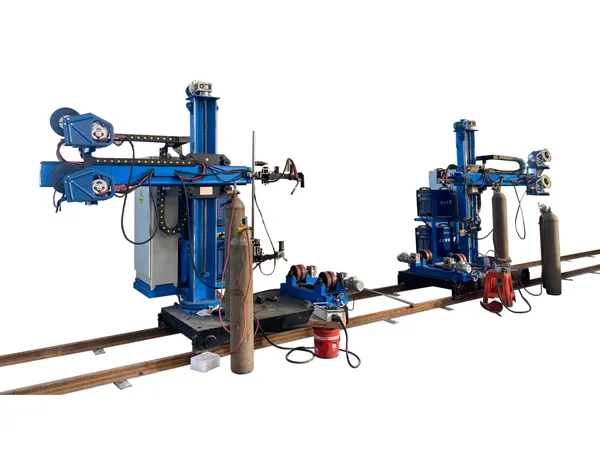

A lead screw welding rotator is a specialized piece of equipment used in welding processes to support and rotate cylindrical workpieces, such as pipes, tanks, or pressure vessels, during welding. The use of a lead screw mechanism allows for precise adjustment of the position and alignment of the workpiece.

Lead screw welding rotator functions

1. Support and Stability of Workpieces:

The primary function of a lead screw welding rotator is to provide stable support for cylindrical workpieces during welding. The rotator’s rollers cradle the workpiece, preventing it from shifting or vibrating, which ensures a consistent weld.

2. Controlled Rotation:

The rotator allows for the controlled rotation of the workpiece. This rotation can be adjusted to the desired speed, which is crucial for achieving uniform welding around the circumference of the workpiece. The rotation speed can be fine-tuned depending on the welding requirements.

3. Precise Positioning and Alignment:

The lead screw mechanism enables precise positioning and alignment of the workpiece. By adjusting the lead screw, operators can move the workpiece horizontally along the axis, ensuring that it is correctly aligned for welding. This is especially important for maintaining the correct distance between the welding torch and the workpiece.

4. Adjustable Roller Distance:

The lead screw welding rotator typically allows for the adjustment of the roller distance to accommodate workpieces of various diameters. The lead screw mechanism makes it easy to change the spacing between rollers to fit the specific size of the cylindrical object being welded.

5. Facilitating Continuous Welding:

By rotating the workpiece at a consistent speed, the rotator allows for continuous welding around the entire circumference without stopping. This continuous motion helps to produce a more uniform and stronger weld.

6. Reducing Operator Fatigue:

The rotator reduces the need for manual handling and repositioning of the workpiece, which decreases operator fatigue and increases safety. Operators can focus more on the welding process rather than on physically managing the workpiece.

…

More detailed information about the lead screw welding rotator functions can be found at: https://www.bota-weld.com/en/a/news/lead-screw-welding-rotator-functions.html