Вибрирующие кормушки Устройства, используемые для непрерывного и равномерного питания массовых материалов на обработчивые машины или конвейеры. Они широко используются в таких отраслях, как горнодобывающая промышленность., металлургия, каменный уголь, строительство, но не обязательно, и пищевая промышленность. Технические характеристики и модели вибрационных питателей различаются в зависимости от области применения., материал, подлежащий обработке, и желаемая мощность.

Технические характеристики вибрационных питателей

Емкость:

Емкость вибрирующих питателей варьируется от нескольких тонн в час (т/ч) до нескольких сотен чемпионат в час. Общие возможности включают 10, 50, 100, 200, и 500 т/ч, в зависимости от модели и приложения.

Размер кормовой палубы:

Ширина и длина кормовой палубы могут варьироваться. Типичная ширина варьируется от 300 мм до 3,000 миллиметровый, и длины варьируются от 600 мм до 6,000 миллиметровый.

Тип фидера:

Электромагнитные вибрарующие кормушки: Идеально подходит для меньших объемов и точных применений кормления.

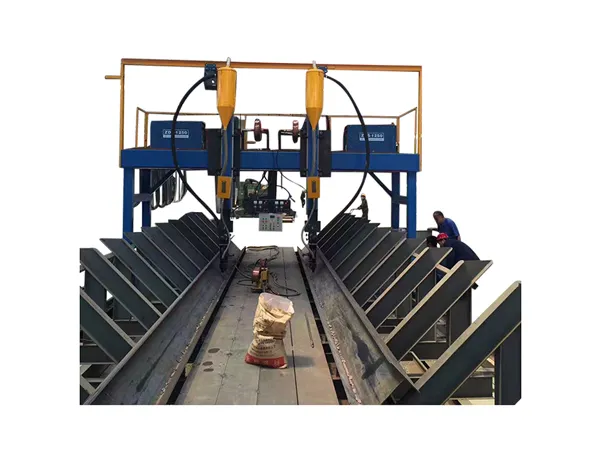

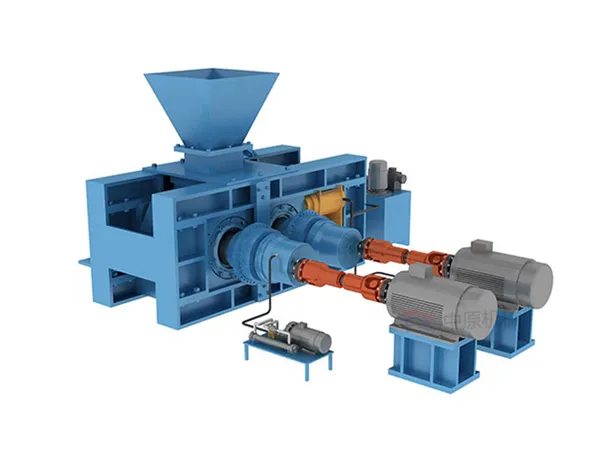

Электромеханические вибрирующие питатели: Подходит для обработки больших нагрузок и для тяжелых приложений.

Вибричики вибрирующих гризли: Эти кормушки имеют стержни гризли для разделения штрафов и используются для обработки материалов с большими размерами комков.

Частота и амплитуда вибрации:

Частота обычно варьируется от 750 Для 3000 Вибрации в минуту.

Амплитуда варьируется от 1 мм до 15 миллиметровый, В зависимости от потока материала и конструкции фидера.

Моторная мощность:

Моторная мощность варьируется от 0.5 кВт до 15 кВт или больше, в зависимости от размера кормушки и емкости.

Материал строительства:

Сделано из различных материалов, такие как углеродистая сталь, нержавеющая сталь, и высокопрочные сплавы, в зависимости от применения и материала для обработки.

Тип установки:

Доступно в стационарном, мобильный, или портативные конфигурации в зависимости от настройки и использования.

…

Для получения более подробной информации о спецификациях и моделях вибрирующих питателей, пожалуйста, нажмите здесь: https://www.zexciter.com/en/a/news/vibrating-feeder-specifications-and-models.html