Explosions in glass tempering furnaces can occur due to a variety of reasons, many of which stem from operational issues, material defects, or improper maintenance. Understanding these causes can help prevent such incidents.

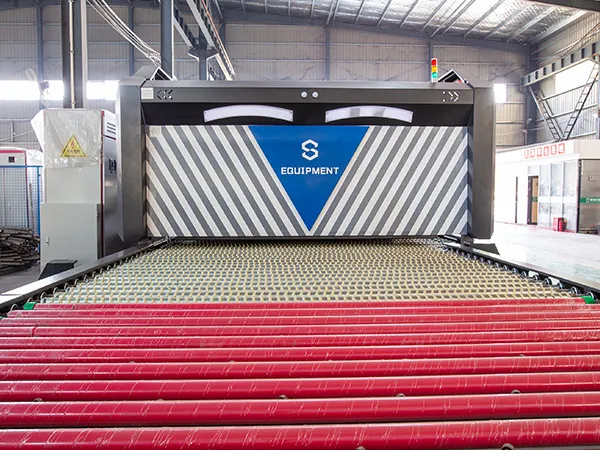

Causes of explosion of glass tempering furnace

1. Glass Defects

Nickel Sulfide Inclusions (NiS): Nickel sulfide inclusions are microscopic impurities in glass that can cause it to shatter spontaneously. These inclusions can expand during the tempering process and lead to delayed failure, sometimes causing the glass to explode after being tempered.

Internal Stresses: If the glass is not properly annealed before entering the tempering process, internal stresses can build up. These stresses can cause the glass to explode under heat or when exposed to rapid cooling.

Surface Defects: Scratches, chips, or cracks on the glass surface can act as stress concentrators during the tempering process, leading to failure and explosion.

2. Incorrect Furnace Settings

Uneven Heating: If the furnace does not heat the glass evenly, it can cause thermal stress. Uneven heating or cooling (quenching) of the glass can lead to differences in expansion and contraction, resulting in glass breakage.

Overheating: Glass that is overheated in the furnace may develop severe internal stresses. When exposed to quenching (rapid cooling), it may fail and shatter explosively.

Incorrect Temperature Gradient: A proper temperature gradient between the heating and cooling sections of the furnace is crucial. If the temperature changes too rapidly or is unevenly distributed, it can cause thermal shock to the glass.

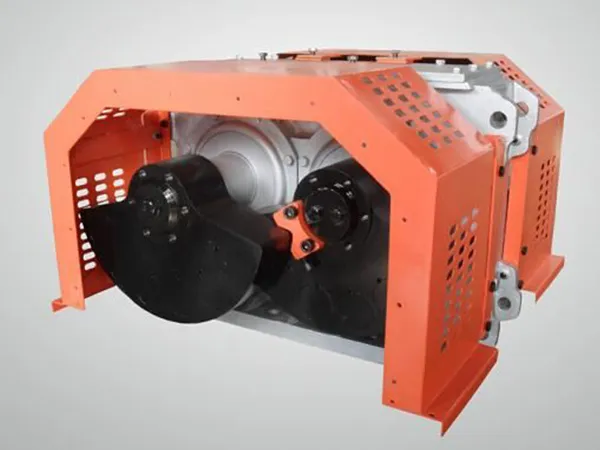

3. Improper Quenching (Cooling) Process

Insufficient or Excessive Cooling: The quenching process, where the glass is cooled rapidly, must be well-regulated. If the cooling is too rapid or uneven, it can lead to a high stress differential between the inner and outer layers of the glass, causing it to shatter.

Improper Airflow: The airflow during quenching should be evenly distributed. Uneven airflow can lead to localized cooling, creating stress points that may cause the glass to break or explode.

4. Furnace Design Issues

Poor Maintenance: A poorly maintained furnace can lead to mechanical malfunctions, uneven heating, or improper quenching, all of which can cause explosions.

…

For more detailed information about the causes of glass tempering furnace explosion, please click here: https://www.shencglass.com/en/a/news/causes-of-explosion-of-glass-tempering-furnace.html