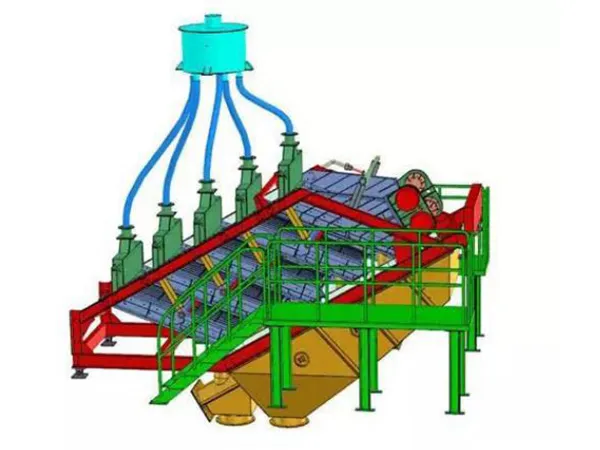

Transportadores de correa in industrial settings, such as coal handling plants, are equipped with various protective devices to ensure the safety of the system, protect the equipment, and safeguard personnel. These devices are designed to prevent accidents, detect malfunctions, and protect against damage to the belt and other system components.

Belt conveyor protection device

1. Pull Cord Switch

Purpose: Emergency stop device.

Función: Pull cord switches are installed along the length of the conveyor belt. When pulled, they trigger an emergency stop of the conveyor, allowing personnel to immediately halt the belt in case of an emergency or malfunction.

Location: Typically mounted on the side of the conveyor.

2. Belt Sway (desalineación) Switch

Purpose: Detects belt misalignment or sway.

Función: The belt sway switch detects the deviation of the belt from its normal path. If the belt starts to drift off-center, the switch signals an alert or shuts down the system to prevent damage or material spillage.

Location: Installed along the edge of the conveyor belt.

3. Belt Slip Switch

Purpose: Detects belt slippage.

Función: This device monitors the speed of the belt and compares it to the drive pulley speed. If the belt is slipping or moving slower than the drive pulley (which indicates belt slippage), the switch will trigger an alarm or stop the conveyor.

Location: Installed near the drive pulley.

4. Zero Speed Switch

Purpose: Detects belt stoppage or slowdown.

Función: Zero speed switches monitor the conveyor’s movement and ensure the belt is running at its designated speed. If the belt stops or slows down unexpectedly, the switch will trigger an alert or stop the conveyor system.

Location: Typically mounted on the tail pulley or drive pulley.

5. Sequence Protection Switch

Purpose: Ensures proper startup and shutdown sequence.

Función: These switches ensure that conveyors start and stop in the correct sequence, preventing material build-up in one section while others are not running.

…

For more detailed information about belt conveyor protection devices, por favor haga clic aquí: https://www.zymining.com/en/a/news/belt-conveyor-protection-device.html