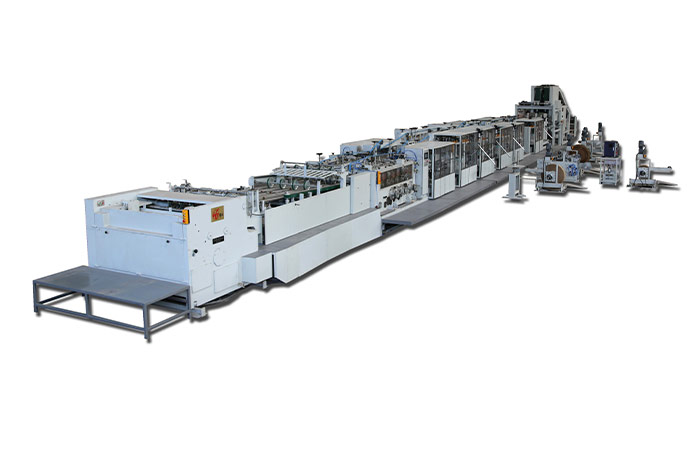

Valve bags are now widely used in our lives, and they are used in different industries. The characteristics of valve pockets are convenient transportation of goods, strong firmness, improved packaging efficiency, low damage rate, and there are many types of valve pockets. The machine manufacturer will now explain to you what are the classifications of valve pockets? Let’s keep reading.

Classification of valve bags

1. Multi-layer kraft paper bag: use two or more layers of kraft paper for further processing on the machine, make it into a bag shape, use polyester thread to reinforce and sew the bottom, and then use heat-sealing paper for heat-sealing treatment .

2. Paper-plastic composite bag: It is also a three-in-one kraft paper bag. The outer layer of the paper bag is kraft paper, and the inner layer of the paper bag is a plastic PP woven bag. EVA, PP, PE and other raw materials are used for high-temperature composite treatment. After completion, according to different Kind of material for one-step bottom treatment.

3. Square bottom open bag: It is basically the same as the multi-layer kraft paper bag. After the semi-finished product is made on the machine, the bottom is manually folded to make a square bottom. The bottom is glued with glue, and then dried by heat sealing or drying. Type processing, complete the production of open bags.

4. Square bottom valve bag: The basic production process is the same as that of the square bottom open bag. The square bottom valve bag is made by a square bottom machine. The valve bag has the same treatment on the mouth and bottom, and at the same time adds a kind of horn to the mouth. mouth, convenient for filling materials.

…

For more details click to visit:https://www.lyhuatianm.com/products-information/classification-of-valve-bags.html