UNA welding production line is a complex assembly setup designed to automate and streamline the welding process, ensuring efficiency, consistency, and quality in the production of welded components. It typically consists of several key components and subsystems, each playing a vital role in the overall operation.

Welding production line composition

1. Workstations

Loading Station: Where raw materials or components are loaded onto the line. This may be manual or automated.

Welding Stations: Dedicated stations where welding operations are performed. There can be multiple welding stations, each handling different types of welds or components.

2. Welding Equipment

Welding Machines: These can be MIG, Tig, spot, laser, or arc welding machines, dependiendo de la aplicación.

Welding Robots: Robotic arms equipped with welding tools for precise and automated welding.

Fuente de alimentación: Provides the necessary electrical energy for the welding process.

3. Conveyance System

transportadores: Transport materials and components between different stations.

Automated Guided Vehicles (AGVs): Move parts around the production line autonomously.

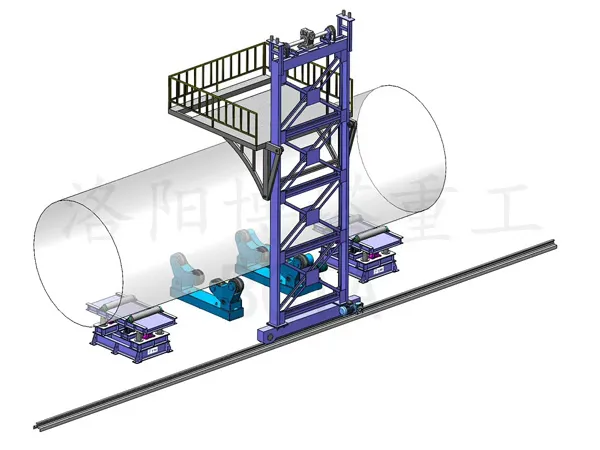

Turntables and Positioners: Rotate and position parts for welding, ensuring proper alignment.

4. Fixtures and Jigs

Clamps and Holders: Secure components in place during welding.

Custom Jigs: Designed to hold specific parts in the correct orientation and position.

…

For more detailed information about the welding production line, por favor haga clic aquí: https://www.bota-weld.com/en/a/news/welding-production-line-composition.html