A vibratory motor is a type of motor used to generate vibrations in machinery and equipment, typically for tasks such as material handling, screening, and conveying. Vibratory motors are essential components in industries like mining, construction, food processing, and manufacturing.Selecting the right vibratory motor is crucial for ensuring the efficiency and effectiveness of vibratory equipment like feeders, screens, conveyors, and other vibrating systems.

Vibration Motor Selection Guide

1. Determine the Application Requirements:

Type of Equipment: Identify whether the motor will be used in a vibrating feeder, screen, conveyor, or another type of vibrating equipment.

Material Characteristics: Consider the type of material being processed (e.g., bulk density, particle size, flowability) as these factors will influence the motor’s power requirements.

Operating Environment: Consider the working environment, such as temperature, humidity, exposure to dust, and whether the motor will operate indoors or outdoors.

2. Calculate the Required Force Output:

Static Moment (Force Output): This is a critical factor in motor selection. It’s typically measured in Newton meters (Nm). The static moment is calculated based on the weight of the material, the equipment, and the desired amplitude of vibration.

Static Moment = Mass x Distance (where mass is the total mass to be moved and distance is the eccentric distance of the motor’s weights).

Manufacturers often provide guidelines or calculators to help determine the correct static moment for specific applications.

3. Determine Motor Size and Power:

Motor Size: Select a motor that can provide the necessary force output. The motor size is directly related to the amount of force it can generate.

Power Rating: Ensure the motor has sufficient power to meet the requirements of the application. Power ratings are typically given in kilowatts (kW) or horsepower (HP).

Speed: Choose a motor with an appropriate rotational speed (RPM). The speed will affect the frequency of vibration. Higher speeds generally result in higher frequencies, which may be suitable for fine materials, while lower speeds are better for coarser materials.

4. Consider the Type of Vibratory Motor:

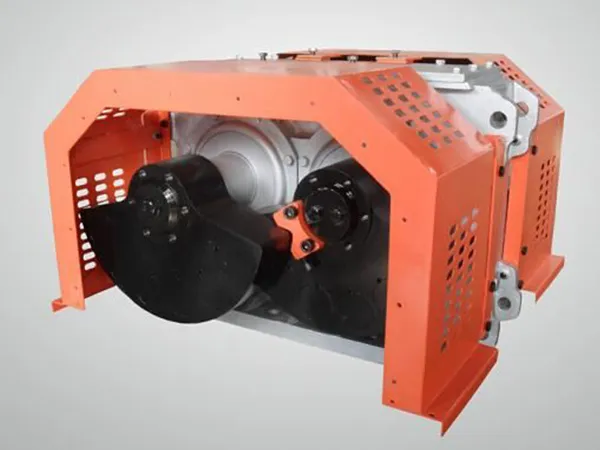

Unbalanced Motor: Typically used for feeders, screens, and conveyors. They generate vibration through an unbalanced weight attached to the motor’s shaft.

Electromagnetic Vibrator: Suitable for applications requiring precise control of vibration and are often used in feeding applications.

…

For more detailed information about the vibration motor selection guide, please click here: https://www.zexciter.com/en/a/news/vibration-motor-selection-guide.html