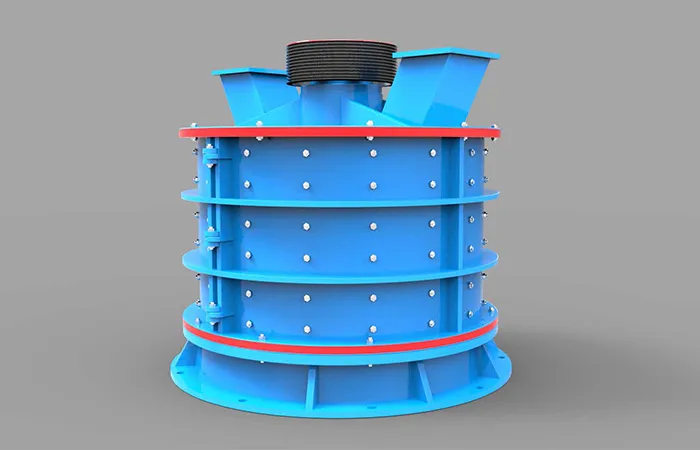

А vertical compound crusher, also known as a composite crusher, combines the principles of impact, измельчение, and crushing to effectively break down materials into smaller sizes. This crusher is widely used in various industries, в том числе майнинг, металлургия, строительные материалы, и химическая инженерия.

Vertical compound crusher technical parameters

Емкость (Т/ч):

Varies depending on the model and material being processed.

Typical range: 10-200 Т/ч.

Feeding Size (миллиметровый):

Maximum feeding size: 50-100 миллиметровый.

It can handle materials with a certain degree of hardness and moisture.

Output Size (миллиметровый):

Регулируемый, обычно 0-5 миллиметровый.

Achieves fine crushing and uniform particle size distribution.

Rotor Diameter (миллиметровый):

В зависимости от модели, rotor diameter can vary.

Common range: 800-2000 миллиметровый.

Rotor Speed (R/мин):

Influences the crushing efficiency and particle size.

Typical range: 800-1500 R/мин.

Power (кВт):

Depends on the size and capacity of the crusher.

Typical range: 22-250 кВт.

Масса (кг):

The weight varies depending on the size and model of the crusher.

Common range: 3000-15000 кг.

Размеры (L x W x H) (миллиметровый):

Varies by model.

α—— Содержание крупности меньше размера сита в сырье: 2100x2000x2200 mm (for a medium-sized crusher).

Reduction Ratio:

Обычно варьируется от 4:1 Для 8:1.

Indicates the efficiency of size reduction.

Material Hardness:

Capable of processing materials with a Mohs hardness of up to 7-8.

Ключевая особенность

Высокая эффективность дробления:

Combines impact, измельчение, and crushing mechanisms to achieve high crushing efficiency.

Adjustable Output:

The output size can be adjusted by altering the gap between the impact plate and the grinding plate.

…

For more detailed information on the technical parameters of vertical compound crusher, пожалуйста, нажмите, чтобы посетить: https://www.zymining.com/en/a/news/vertical-compound-crusher-technical-parameters.html