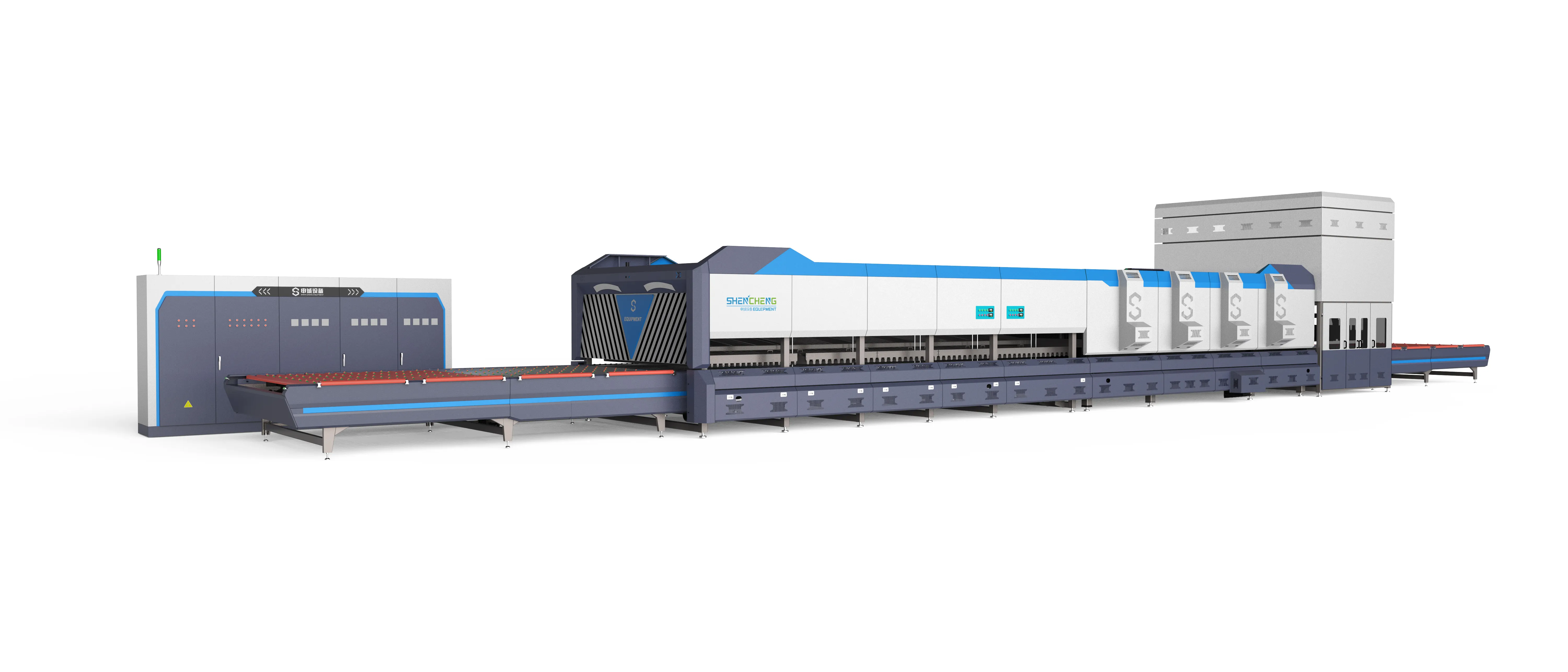

UNA tempering furnace is a device used to process glass. It gives the glass strength and safety through a process of heating and rapid cooling.Tempering is a heat treatment process that increases the toughness and ductility of a material while reducing its hardness and brittleness.

Types of Tempering Furnaces

Batch furnaces: These furnaces process a specific batch of material at a time, suitable for small to medium production volumes.

Continuous furnaces: Designed to process materials continuously, offering high production capacity.

Electric furnaces: Utilize electric heating elements for precise temperature control.

Gas furnaces: Use gas as the heating medium, offering cost-effective operation.

Tempering Furnace Operation Process

1. Preparación

Load the furnace: The pre-hardened material is loaded into the tempering furnace. This could be done manually or using automated systems depending on the size and type of furnace.

Select the heating medium: The furnace uses a heating medium like air, salt bath, or oil, depending on the material and desired temperature.

Set the temperature and time: The operator sets the desired tempering temperature and time based on the material and desired properties.

…

For more detailed information about the tempering furnace operation process, por favor haga clic aquí: https://www.shencglass.com/en/a/news/tempering-furnace-operation-process.html