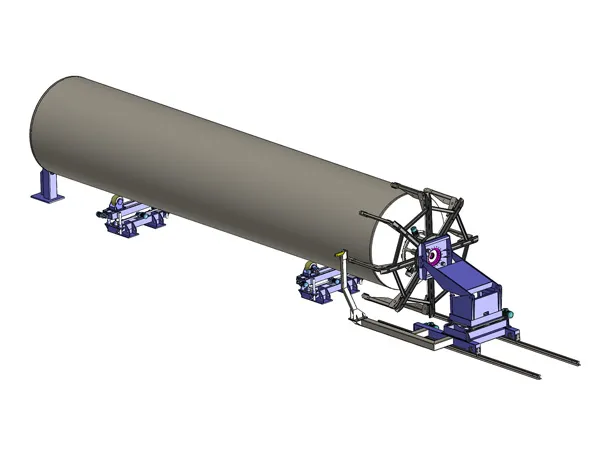

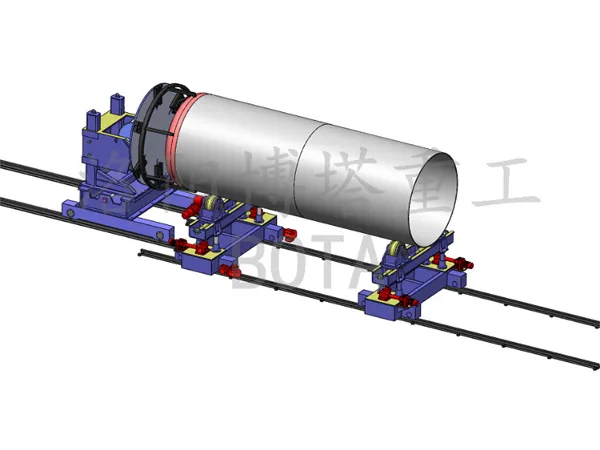

А storage tank welding production line is a specialized setup designed for the efficient manufacturing of storage tanks used in various industries, such as oil and gas, химикаты, С развитием современной промышленности, и пищевая промышленность.

Key Components of Storage Tank Welding Production Line

Подготовка сырья:

Sheets of steel or other materials are cut to size and prepared for welding.

Welding Stations:

Automated or semi-automated welding machines perform various types of welding (например, ТИГ, МНЕ, или погруженная дуга) to join tank components.

Assembly Line:

Components are assembled in a sequential manner to streamline production.

Inspection Stations:

Quality control measures, including visual inspection and non-destructive testing, ensure weld integrity and overall quality.

Finishing Area:

Tanks are finished through processes such as grinding, painting, or coating to enhance durability and corrosion resistance.

Storage and Logistics:

Finished tanks are stored or transported for installation or further processing.

Storage Tank Welding Production Line Production Process

Дизайн и планирование:

Detailed plans are developed, often using CAD software, to specify dimensions and material requirements.

…

For more detailed information about the process flow of the tank welding production line, пожалуйста, нажмите здесь: https://www.bota-weld.com/en/a/news/storage-tank-welding-production-line-process.html