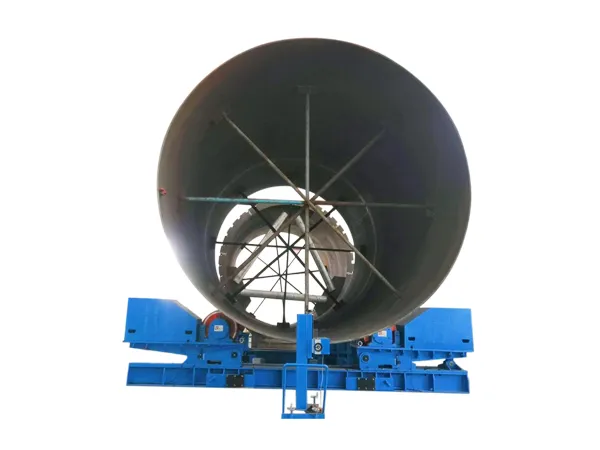

Pipe welding rotators are specialized equipment used in the welding industry to assist in the fabrication and welding of pipes, vessels, and other cylindrical workpieces. These rotators are designed to rotate the workpiece at a controlled speed during the welding process, allowing for precise and efficient welding.

Pipe welding using a welding rotator typically involves several steps to ensure proper alignment, сварка, and quality control. Here’s a general outline of the welding steps involved:

Подготовка:

Clean the pipe surfaces to be welded thoroughly to remove any dirt, ржавчина, or contaminants that could affect the weld quality.

Ensure proper fit-up of the pipes to be welded, aligning them accurately to minimize gaps and ensure even welding.

Set-Up:

Position the pipes on the welding rotator, ensuring that they are securely held and balanced to prevent movement during welding.

Adjust the welding rotator speed and angle to suit the welding process and the specific requirements of the job.

Tack Welding:

Use tack welds to temporarily hold the pipes in place while welding. Tack welds help maintain alignment and prevent distortion during the welding process.

Tack welds should be placed strategically along the length of the joint, typically at regular intervals.

Root Pass Welding:

Begin the welding process by laying down the root pass. This is the first weld bead deposited in the joint.

Depending on the welding procedure and requirements, the root pass may be deposited using techniques such as TIG (Вольфрамовый инертный газ), МНЕ (Металл Инертный Газ), or SMAW (Shielded Metal Arc Welding).

Filler Passes:

After the root pass is complete, additional filler passes are deposited to fill the joint and build up the weld.

The number of filler passes required depends on factors such as the thickness of the pipe and welding specifications.

Cover Pass:

Once the joint is adequately filled, a cover pass is applied to the weld to ensure complete penetration and to provide a smooth, even surface finish.

The cover pass helps improve the appearance and integrity of the weld.

…

For more detailed information on the welding steps of the pipe welding roller machine, пожалуйста, нажмите, чтобы посетить: https://www.bota-weld.com/en/a/news/pipe-welding-rotator-welding-steps.html