The truck crane slewing bearing is an important “joint” of the crane, so its maintenance is very important. So how to maintain the truck crane slewing bearing?

When carrying out maintenance work, the first thing to be aware of is the risk of being dragged into the rotating pinion, crushing and shearing.

When performing the following tasks, ensure that no maintenance personnel are in the danger zone between the main boom, upper carriage and roller, or between the lower carriage and roller when starting the engine to perform the necessary swing and luffing movements. Hazardous area, except for the crane operator (in the cab).

Check the bolts of the truck crane slewing bearing

1. Before the crane works each time or at least once a week, visually check the bolts on the slewing bearing;

2. After the first 100 working hours of the slewing bearing, check whether the bolts are loose, and then check again at the 300th working hour; after that, check every 500 working hours; shorten the inspection interval for severe working conditions. If the bolts are found to be loose during the inspection, please stop the construction work and contact the local after-sales service department immediately, and the factory or professional technicians will inspect and decide whether to dismantle and inspect immediately;

3. The slewing bearing is filled with lithium-based grease before installation;

4. When replacing the bolts, wipe the bolts clean, apply thread fastening glue and then tighten them; use a crane according to the requirements of the operation manual and lifting performance table, or check the fastening bolts regularly according to the requirements, so as to avoid fatigue damage of the bolts Danger;

Routine inspection of truck crane slewing bearing

1. Regularly check the flexibility of rotation; if noise and impact are found, stop the machine immediately for inspection, troubleshoot, and disassemble if necessary;

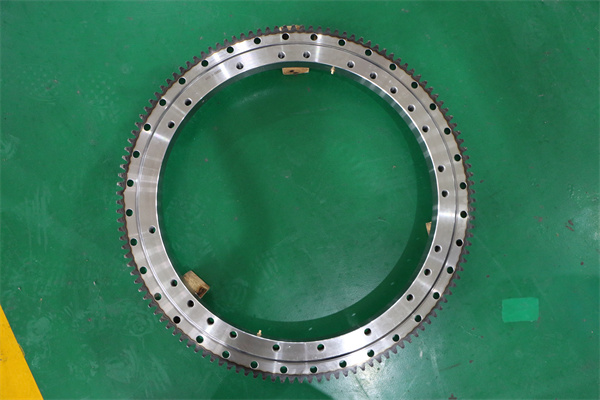

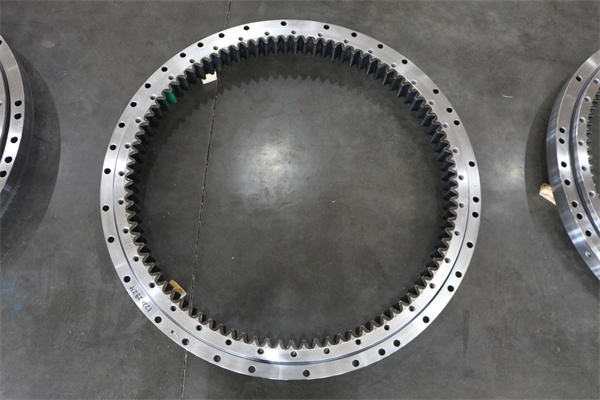

2. Regularly check whether the rotary ring gear is cracked or damaged, and whether the meshing tooth surface has bite, gnawing, tooth surface peeling, etc.;

3. Regularly check the integrity of the seal. If the seal is found to be damaged, it should be replaced in time, and if it is found to be falling off, it should be reset in time.

Lubricate the tooth surface of the truck crane slewing bearing

The ring gear of the slewing ring has been coated with anti-rust oil before leaving the factory. The validity period of this anti-rust is generally 3 to 6 months. After the expiration date, it should be coated with anti-rust oil in time.

In addition, in use, prevent the slewing bearing from being exposed to direct sunlight. It is forbidden to wash the slewing bearing directly with water, so as to prevent water from entering the raceway, and strictly prevent hard foreign objects from approaching or entering the meshing area of the teeth.

More detailed information on truck crane slewing bearings can be accessed by clicking: https://www.excavatorbearing.com/Slewing-bearing-for-truck-crane.html