The density of the lost foam pre-expanded beads determines the density and degree of fusion of the various parts of the die, and the quality of the die determines the quality of the casting. The main factors affecting the density of the pre-expanded beads of the lost foam are the quality of the raw materials and the performance of the pre-foaming machine. The use of raw materials that meet the requirements of the lost foam process and the high-performance pre-expanding machine for the lost foam can achieve the same density disappearance. Mold pre-expanded beads.

Loss-mode pre-expanded beads of uniform density are the basis for the production of high quality molds. As the first process of lost foam casting, the pre-issue t-package is the most important part of lost foam casting.

1. The importance of the quality of the lost mode die

1. 1 The importance of the quality of the lost mode die

As one of the most advanced casting processes in the world, lost foam casting can achieve precision casting precision.

The lost foam casting line consists of three parts: self-region, yellow zone and black zone. From the pre-fabrication of raw materials to the casting of castings, after a series of production processes, there are many factors that affect the quality of the chess pieces. Kind. According to the statistical analysis of the defects of the lost foam casting, 70% of the casting defects are caused by the poor quality of the die. Once the die is manufactured, its quality is difficult to adjust in the subsequent process. The quality of the die determines the quality of the lost die casting. The high quality die is the primary prerequisite and guarantee for the production of high quality castings.

1. 2 Main features of high quality lost foam die

1) The die is evenly filled and the density of each part is consistent.

2) The consistency of the beads is consistent

3) The surface of the die is smooth and flat

4) Accurate die only inch

1.3 How to get high quality lost mode die

1) Use suitable materials that meet the lost foam production process.

2) Using a high-performance foaming pre-expansion machine to obtain pre-expanded beads of uniform density, thus ensuring uniform density and uniformity of the die.

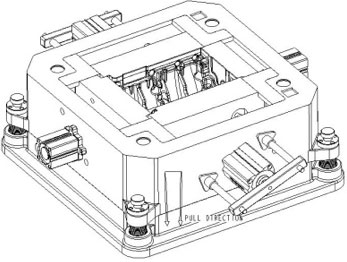

3) Using a high-performance automatic mold and mold for the lost-foam mold, the scientific mold forming process is designed to ensure that the parts of the mold are evenly filled, and the precise size and perfect bead fusion degree are obtained.

2. Effect of pre-expanded bead density on die and casting

2.1 Effect on density, fusion and surface finish of the die

The pre-expanded beads have the same density and uniform particle size, and the density of each part of the produced die is uniform, the degree of fusion is uniform, especially the surface finish is high, the casting defects can be reduced, and the quality and surface finish of the casting can be improved.

2.2 Influence on castings of multiple pieces

In the lost foam production process, more than 85% of the models need to be sliced and then bonded into a complete model. Generally, the die is divided into 2-3 pieces, and the complex one needs to be divided into 4- 5 pieces. If the density of the pre-expanded beads is inconsistent when the sheets are formed, the density of each part of the mold after bonding may be deviated. The density deviation of each sheet exceeds 0.6 g / liter, which will cause scratch casting defects. The density deviation of each part of the model is large. When the temperature and speed of the casting are the same, the burning speed, combustion decomposition and gas generation of the model are constantly changing. It is easy to bonfire (back spray) during casting, and the casting is easy to cause wrinkles ( Defects such as carbon deposits, pores, oversize and deformation.

3. Analysis of the influence of the quality of raw materials on the density of pre-expanded beads

3.1 Quality of raw materials

At present, there are no EPS materials for the lost molds in China, and most of the lost foam companies use EPS materials for packaging. Compared with the EPS material used in the lost mold of Styrochem, the stability of the raw material is slightly worse.

3. 1. 1 Feng Li Trail

The particle size consistency of the domestic EPS raw materials is poor, and the particle size fluctuation of the beads after pre-expansion is large, which will affect the degree of fusion and surface roughness of the various parts of the die, and reduce the quality of the casting.

3. 1. 2 amylose content

The content of pentamidine is an important factor affecting the quality of pre-expansion of beads. The content of pentamidine in EPS is most suitable for pre-expansion at 5.9%-6.5%. The content of pentamidine in the EPS is inconsistent, and it is necessary to constantly adjust the parameters of the pre-foaming machine to stabilize the density during pre-carrying. There are many factors affecting the change of the content of pentane, such as: the fluctuation of the content of pentamidine in the domestic EPS itself is large. The volatilization of the amylose v. caused by the change of the temperature during storage and transportation of the raw material manufacturer. The pentylene is volatilized.

After the same batch of EPS raw materials arrived at the factory for 7 days, 3 bags were randomly selected for testing. The content of pentamidine in the 3 bags of raw materials was inconsistent (9%, 7.8%, 7.3%, respectively), and the results of 14 days, 21 days… 54 days later It shows that in the same batch of EPS raw materials, the content of pentamidine and the rate of volatilization of amylose are also different. Therefore, it is difficult to produce a high-quality die using a material having a large particle diameter error and an inconsistent EP material.

4. Analysis of the effect of foaming machine performance on the density of pre-expanded beads

After long-term application, domestic lost foam enterprises have realized the importance of bead pre-expansion and die-forming in lost foam casting.

4.1 Performance analysis of domestic pre-expander

1) Steam pressure control is inaccurate, the degree of drying of the beads is inconsistent, and the curing time cannot be accurately controlled. The pre-expanded beads have a density fluctuation of 1.3 – 2.4 g.

2) The accuracy of the feed weighing is low, the weighing deviation is 8 – 9%, so that each time

The weight of the beads entering the pre-expansion chamber varies, and at the same vapor pressure and pre-expansion time, the higher the feed, the higher the density, and the lower the feed, the lower the density.

3) No density detection and feedback control device, manual adjustment of pre-fire gun parameters based on manual experience.

4) Sometimes pre-expanded beads are agglomerated to form a dead material.

5) The beads remaining in the pre-expansion chamber after each pre-expansion cannot be removed. When the content of pentamidine in these beads volatilizes to a lower level, a dead material is formed, and the dead material cannot be in the molding machine. Perform secondary foaming. When the dead material is mixed into the next batch of pre-expanded beads and transported to the molding machine to form the die, they will shrink, resulting in inconsistent bead density and degree of fusion inside the die, and formation of holes in the surface of the die. , causing scratch casting defects, causing loose casting and slag holes.

5. Germany Teubert lost mode special pre-expansion hunger

Germany Teubert intermittent foaming mold pre-foaming machine, fully automatic pre-foaming production, the operator only needs to input the target density of the beads into the control computer, the system will automatically adjust the parameters and control the density.

Main performance characteristics:

1) Fully automatic production, suitable for EPS and copolymer pre-expansion, foam chamber temperature can be adjusted from 70 °C -13O”C, steam chamber can be adjusted at any time, steam pressure control accuracy O.Olbar The density fluctuation after pre-expansion of domestic beads is: 1:0.3 g, the density fluctuation after pre-expansion of imported beads is: 1:1 g

2) Proprietary density control device, fully automatic detection of the density of pre-expanded beads per beat, and feedback to the PLC to adjust various parameters, full-closed detection and adjustment parameters, reducing external factors on the pre-foaming machine Interference ensures the accuracy of density control.

3) Automatic weighing and adjusting the weight of the beads entering the pre-expansion chamber each time, the feeding weighing accuracy is high, and the weighing deviation is less than 2%.

4) The proprietary pre-foaming chamber design facilitates the cleaning of residual beads and avoids the mixing of dead materials into the next batch of pre-expansion operations, ensuring the quality of the die and castings.

5) The fluidized drying bed with adjustable temperature ensures the uniform drying degree of the beads and better controls the curing time.

6. How to get the density – honey i Xiao lost mold pre-package rough recommendations

6.1 Selection of raw materials

It is preferred to select the special materials for the lost foam with uniform particle size and stable pentane content; or to meet the requirements of the lost foam process, select raw materials with smaller particle size and relatively stable pentamidine content, and reduce the raw material to the die and casting. The impact of quality.

6. 2 Storage of raw materials

When the raw materials are shipped from the factory, they are packed and transported in a sealed container. When the raw materials arrive at the factory, they are stored in a special constant temperature storage room. The temperature of the storage chamber is stabilized at 15″C -20 .C, which is as slow as possible. The volatilization rate keeps the content of pentamidine stable.

6.3 Selection of pre-foaming machine

The performance of the domestic pre-foaming machine is not good, but the price is straight, the imported pre-foaming machine has superior performance, but it is expensive. The performance of the pre-explosive gun is an important factor affecting the uniform density of pre-expanded beads. Try to use a high-performance lost-mode special pre-emphasis machine to obtain stable high-quality pre-expanded beads. After selecting the right raw materials and the pre-emphasis machine for the lost foam, the pre-expanded beads with uniform density can be obtained, which makes it possible to produce high-quality molds and lays a foundation for the production of high-quality castings.