Lost foam casting is mostly made of foam as a mold, and is also called “dry sand solid casting” and “negative compact casting” in China. In the casting process, it includes the design of the riser system, the pouring temperature control, the pouring operation control, the negative pressure control and other links, which need to be strictly controlled. Once a problem occurs in a certain link, the quality of the casting will be affected.

First, the principle of lost foam casting production

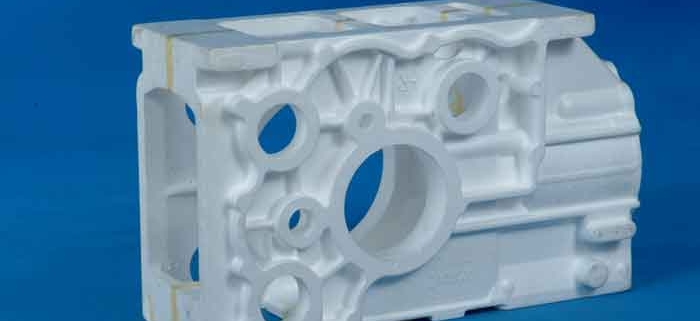

Use a polymer material such as EPS, STMMA or EPMMA to make a solid mold of the same structure and size as the part to be cast. After dip-coating refractory coating (strengthening, smoothing, and venting) and drying, Buried in dry quartz sand through three-dimensional vibration modeling, the cast casting sand box is poured into the molten metal liquid under negative pressure, so that the polymer material model is heated and gasified, and then replaced by liquid metal to form a one-time molding. A new casting method for casting new castings.

Second, the process control of lost foam casting

The main process includes: pouring riser system design, pouring temperature control, pouring operation control, and negative pressure control.

The gating system plays an important role in the lost foam casting process and is a key to the success of casting production. Due to the wide variety of castings and the different shapes, the specific production processes of each casting have their own characteristics and vary widely. These factors directly affect the accuracy of the design results of the gating system.

The design of the gating system is somewhat different from the traditional sand casting. In the design of the gating system, the particularity of the process should be taken into account. The cross-sectional dimensions of the various parts of the gating system are related to the size of the casting, the combination of the model clusters and the number of pieces per box.

The combination of model clusters can basically reflect the characteristics of the casting and the form of the filling of the casting. Due to the existence of the model cluster, the behavior of the molten metal after pouring is quite different from that of sand casting. The model gasification needs to absorb heat during the casting process, so the casting temperature of the lost foam casting should be slightly higher than that of the sand casting. For different alloy materials, the casting temperature of the lost foam casting is generally controlled at 30 to 50 ° C higher than that of sand casting. The heat of the molten metal higher than 30 to 50 ° C can satisfy the heat required for the model gasification. If the casting temperature is too low, the casting is prone to defects such as insufficient pouring, cold separation, and wrinkle. Casting temperatures are too high, castings are prone to defects such as sand.

When designing the cross-sectional dimensions of each part of the gating system, the resistance due to the existence of the model during the casting of the molten metal in the lost foam casting should be considered. The minimum flow blocking area should be slightly larger than the sand casting.

Negative pressure is a necessary measure for lost foam casting of black alloys. The role of negative pressure is an important guarantee for increasing the strength and stiffness of sand, and it is also the main measure to eliminate the gasification products of the model. The size and retention time of the negative pressure is related to the material of the casting and the structure of the model cluster and the coating. For coatings with good gas permeability and coating thickness less than 1mm, the negative pressure of cast iron parts is generally 0.04~0.06MPa, which is the upper limit for steel castings. For the cast aluminum parts, the negative pressure is generally controlled at 0.02 to 0.03 MPa. The negative pressure holding time depends on the model cluster structure. When the number of model clusters in each box is large, the negative pressure holding time can be appropriately extended. Generally, the negative pressure is stopped when the solidified crust of the surface of the casting reaches a certain thickness. For thicker coatings and poorer gas permeability of the coating, the negative pressure and holding time can be appropriately increased.

Third, the precautions for lost foam casting

The most taboo of the lost foam casting casting operation is intermittent casting, which is easy to cause cold insulation defects in the casting, that is, the temperature of the molten metal poured first decreases, resulting in a cold separation between the molten metal and the post-casting metal. In addition, the lost foam casting system mostly uses a closed casting system to maintain the smoothness of the casting. In this regard, the form of the gate cup is closely related to whether the pouring operation is stable. When pouring, keep the liquid level in the pouring cup stable and make the pouring dynamic head stable.