La pantalla de relajación y Pantalla vibrante Ambos se utilizan en diversas industrias para procesar materiales., pero operan basándose en principios diferentes y cumplen funciones diferentes.

Diferencia entre pantalla de relajación y pantalla vibratoria

1. Principio de operación:

Pantalla de relajación:

Una pantalla de relajación generalmente se refiere a un tipo de pantalla donde se permite que el material que se procesa se asiente o “relajarse” mientras se mueve por la superficie de la pantalla. Esto permite que las partículas encuentren huecos naturales y caigan a través de la malla más fácilmente..

Por lo general, se basa en la gravedad y el movimiento controlado del material., Permitir que las partículas finas pasen a través de las aberturas sin agitación significativa..

Este método es más adecuado para materiales delicados o frágiles que podrían dañarse con un movimiento vigoroso..

Criba vibratoria:

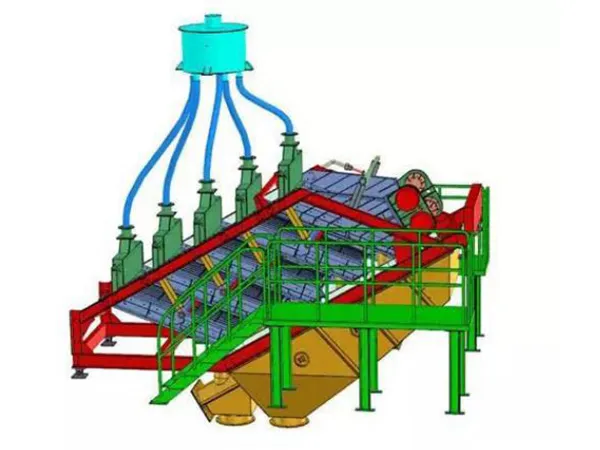

Una criba vibratoria funciona mediante el uso de un motor para crear vibraciones que agitan el material que se criba.. Toda la superficie de la pantalla vibra, haciendo que el material se mueva en una dirección específica.

La vibración constante ayuda a separar partículas de diferentes tamaños de manera más eficiente.. Las cribas vibratorias suelen ser más agresivas y están diseñadas para procesar grandes volúmenes de material en periodos más cortos..

Vienen en varios tipos., como circular, lineal, o movimiento elíptico, dependiendo del mecanismo de vibración utilizado.

2. Intensidad del movimiento:

Pantalla de relajación:

Tiene movimiento suave, que permite que los materiales se asienten y encuentren espacios naturales por los que puedan pasar. Hay poca o ninguna agitación, confiar más en el flujo del material a través de la pantalla.

Adecuado para materiales finos o delicados que necesitan un manejo menos contundente.

Criba vibratoria:

La superficie de la pantalla experimenta vigoroso, vibraciones repetidas, que obligan al material a moverse a través de la pantalla de forma controlada. El movimiento ayuda a separar materiales finos y gruesos rápidamente..

Ideal para aplicaciones de servicio pesado, como la minería, construcción, y procesamiento de material a granel.

3. Aplicación y materiales procesados:

Pantalla de relajación:

A menudo se utiliza para cribado fino y materiales sensibles a daños o roturas.. Los ejemplos incluyen el procesamiento de partículas frágiles., polvos, o sustancias granulares.

Se puede utilizar en el procesamiento de alimentos., industrias quimicas, o cualquier aplicación donde sea esencial un manejo suave.

…

Para información más detallada sobre la diferencia entre pantalla de relajación y pantalla vibratoria, por favor haga clic para visitar: https://www.zexciter.com/en/a/news/difference-between-relaxation-screen-and-vibrating-screen.html