Хотя современное оборудование является незаменимым фактором в обеспечении качества продукции, роль форм в литье тоже очень важно. Специально для производителей из алюминиевого сплава и алюминиевых сплавов автозапчастей, точность и долговечность алюминиевых литейных сплавов пресс-формы оказывают очевидное влияние на качество продукции.

Для получения цветного литья металла, форма больше для образования полости пресс-формы. В общем, сама пресс-форма не является непосредственно в контакте с расплавленным металлом, особенно для отливок формы неметаллических со сложными формами, и контакт с горячей металлической жидкостью является формой. Материал, в основном формовочный песок, делает моделирующий материал одним из основных факторов, влияющих на качество отливки. Литья из алюминиевого сплава силы тяжести отличается. Из-за более низкой температурой плавления алюминиевого сплава, производительность литья хорошо. В массовом производстве, the shape of the casting is generally formed directly by the mold, such as the aluminum alloy cylinder and the cylinder head of the engine. It is beneficial to improve labor productivity, and more importantly, to control the structure and grain size of castings by adjusting the temperature distribution of different parts of the mold, improve the quality of castings, and at the same time avoid environmental pollution caused by the use of modeling materials. The labor conditions of the workshop.

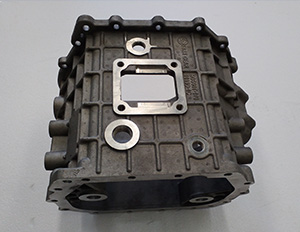

As the shape of the casting is different, the aluminum alloy gravity casting molds are also different. Even in the same part, different casting processes are used, and the mold forms are often different, but in any case, aluminum alloy gravity casting molds have their commonalities.

Первый, you must choose the right casting process.

The quality of the casting process is directly related to the quality of the casting and the rate of the production. Some mold manufacturing factories in China have begun to use the solidification simulation to carry out the casting process auxiliary design. Through the computer simulation of the filling and solidification process, the hot junction parts which are easy to produce casting defects are found and overcome, which is reliable for improving the casting process design. Sex, it is very important and effective to effectively prevent the mold from being reworked during the debugging process.

Второй, the mold must have good heat capacity.

The thicker formwork and modules that meet the requirements are not only an effective guarantee for the life of the mold, but also have a very important role in the adjustment of the temperature field during continuous working of the mold. In order to reduce the cost and save the materials, some mold factories blindly reduce the effective thickness of the mold to achieve the purpose of reducing the weight. Однако, this not only greatly reduces the service life of the mold, but also makes the casting easy to deform and affects the dimensional accuracy of the casting. Will lead to the scrapping of castings, causing damage to the foundry, and more seriously damage the reputation of the mold factory itself.

Третий, the mold must have a more reliable cooling system and a gas extraction system.

Through cooling, not only can labor productivity be effectively improved, but also the temperature field of the casting can be adjusted, and the cooling rate of the casting can be controlled, thereby affecting the internal structure and grain size of the casting and achieving the purpose of effectively controlling the mechanical properties of the casting. Как следует из названия, the gas is extracted artificially to discharge the gas inside the cavity to the cavity to reduce the possibility of pore defects in the casting. В то же время, the mold temperature can be adjusted in a small area by adding a vent plug, which plays an important role in preventing and overcoming the cracking and collapse of the aluminum alloy.

четвертый, there must be a mold positioning device and a convenient mold mounting system that match the casting machine.

The positioning device not only ensures the casting size, reduces the crevice and burr, but also ensures the normal operation of the casting machine. It can be said that there is no good positioning device without a good positioning device. The mold must be easy to install and disassemble. Because aluminum alloy>aluminum alloy gravity casting, the mold must be removed and repainted and repaired at regular intervals. If the disassembly is inconvenient, it will increase the labor intensity of the workers and take up more labor. Time, reduce production and efficiency.

For foundries, высококачественные формы означают высококачественные отливки, что означает более низкие затраты, более высокая производительность и прибыль.