Aluminum Alloy Casting

Relying on Liushi mould excellent talents, mature technology,huge design team and years of experience, Luoyang Liushi Mould Aluminium Alloy Castings Zhenzhu Machinery Branch (Luoyang Zhenzhu Machinery Manufacturing Co., Ltd ) was established in 2015.

Zhenzhu Machinery covers an area of 15,000 square meters, with a comprehensive office building of 3,000 square meters and a large comprehensive workshop of 10,000 square meters.

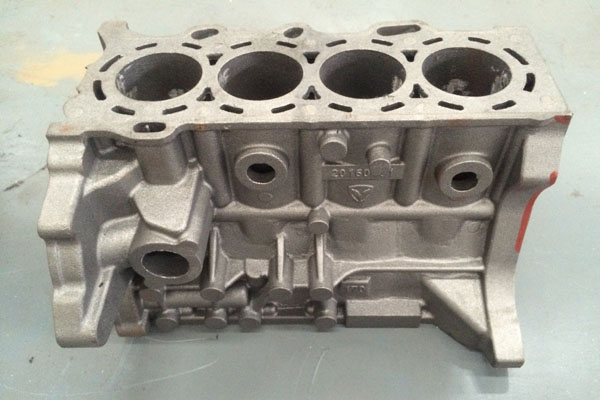

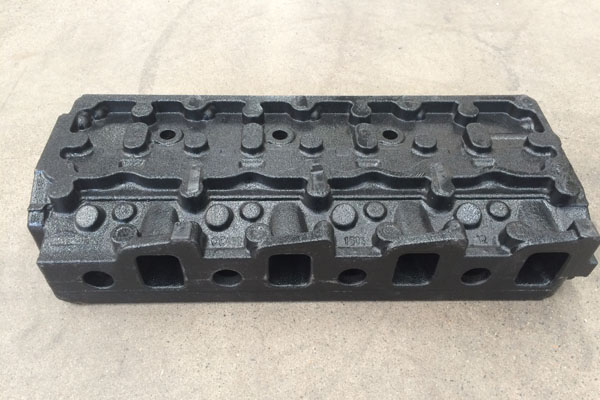

Zhenzhu Machinery has mature lost foam casting process and gravity casting process. We have 2 automatic casting production lines of lost foam process, which main procedure are operated by manipulator. We have a automatic line of T6 heat treatment, 1 set EPS foaming machine, 2 set 1000kg centralized melting furnaces, 6 sets 600kg graphite crucible furnaces, 1 set automatic HS – CXJ – 3200 high efficiency and energy-saving molding machine, 15 sets of other model white pattern molding machine, 1 set plain bumper with the same advanced performance as American Fukang brand, 1 set density equivalent meter, 1 set Fosco dusting machine; 2 sets Aluminum alloy gravity pouring and turning machine, 3 sets Coated sand core-making machine , 1 set X-ray flaw detection spectrometer, 1 set Metallographic analyzer, 1 set Hexagon coordinate measuring instrument, 1 set scanner and more than 20 sets of other corollary equipment. Not only we can supply with Aluminum Alloy Castings, Grey Iron Castings and Ductile Iron Castings, but also we can supply with machined finished parts. Only the capacity of Aluminum Alloy Castings can reach up to above 10000 tons every year. Our products include: engine cylinder block, cylinder head, gearbox housing, clutch housing, steering gear housing, robot manipulator, pressure shell, volute, motor casing, intake pipe, bracket flywheel housing, new energy vehicles parts and various aluminum alloy products.

Our company has passed IATF16949 system certification. With the excellent production management system and quality guarantee system, we can make sure supply high quality products for our clients. So far we have supplied tens of thousands of pieces of gearboxes, clutch shells, combustion engine accessories, volute and other products for Fastre, a foreign trade company in Beijing and a enterprise in Taiwan, the qualified rate can reach up to 95% .

Luoyang Zhenzhu Machinery Manufacturing Co., Ltd provide one-stop service for customers with process design, simulation of casting, mould development, white pattern molding, sand core making, aluminum alloy casting, shot blast cleaning, flaw detection, aluminum alloy castings’ delivery and etc . We have a strong mould design team, unique core technology, and we promise to provide the best quality castings for our customers.Welcome all the customers to negotiate and cooperate!

We anticipated hand in hand cooperates with you, altogether create magnificently!

Aluminum alloy casting process

The aluminum casting is a device device of pure aluminum or aluminum alloy obtained by a casting process. Generally, a sand mold or a metal mold is used to pour aluminum or aluminum alloy heated to a liquid state into a cavity, and the obtained aluminum parts or aluminum alloy parts of various shapes and sizes are generally referred to as aluminum die castings.

About aluminum alloy casting process (sand casting)

Sand castings are the most popular and simplest types of castings that have been used for centuries. Sand casting is used to make sand castings for large parts such as grey cast iron, ductile iron, stainless steel and other types of steel. The main steps include painting, moulding, core making, styling, melting and pouring, cleaning and more.

mapping:

The traditional method is to take the foundry drawings and then send the drawings to the foundry. This process can be done in the quotation. Today, more and more customers and foundries use computer-aided design instead.

Mold:

In sand casting, the mold is made of wood or other metal materials. In this process, we asked our engineers to make the mold size slightly larger than the finished product, and the difference is called the shrinkage allowance. The purpose of this is to melt the metal into the mold to ensure that the molten metal solidifies and shrinks, thereby preventing voids in the casting process.

Core:

The core is formed by casting resin sand into a mold to form a casting of the inner surface. Therefore, the gap between the core and the mold eventually becomes a casting.

forming:

A mold is required during the smelting process. Molding typically involves the support frame of the mold, which is pulled out to separate during the casting process, where the previously placed core melts in the mold and then closes the die opening.

clean:

The purpose of cleaning is to remove sand, sand and excess metal in the casting. Welding, sand removal can improve the appearance of the casting surface by burning the sand and the scale is removed to improve the appearance of the surface of the casting. Excess metal and other risers are removed. Further steps such as welding and grinding. Finally check the defects and the overall quality.

sort out:

Before processing, re-processing. According to the requirements of different customers, we can do heat treatment, surface treatment, additional inspection and so on.