A mobile compactor, also known as a mobile compactor storage system, is a space-saving solution commonly used in warehouses, offices, and libraries to maximize storage efficiency. Its working principle involves a system of movable racks or shelves mounted on a set of tracks.

Mobile Compactor Working Principle

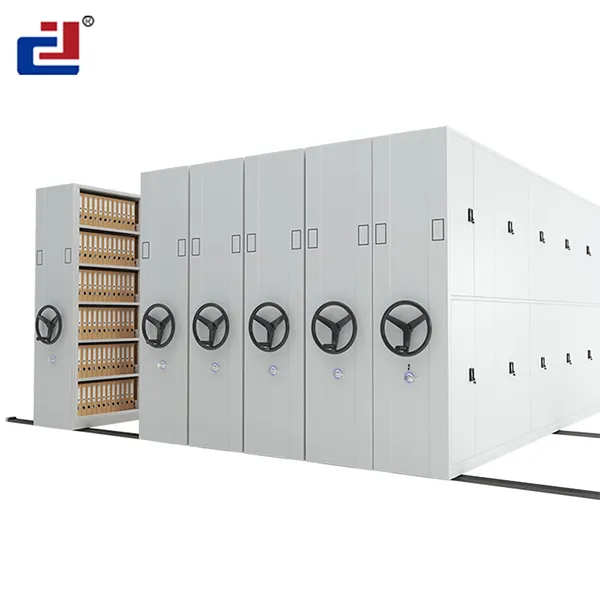

Structure and Components

Racks/Shelves: The storage units where items are kept.

Tracks/Rails: Fixed on the floor, guiding the movement of the racks.

Drive Mechanism: Can be manual (hand-crank) or powered (motorized) to move the racks along the tracks.

Safety Features: Include anti-tilt mechanisms, safety locks, and sensors to prevent accidents.

Operation:

Initialization: The racks are initially positioned along the tracks with minimal space between them to save space.

Accessing Items: To access items in a specific rack, an operator uses the drive mechanism (manual or motorized) to move the racks, creating an aisle.

Movement: The racks glide smoothly along the tracks, creating an open space (aisle) for the user to access the desired items.

Closing: After accessing the items, the racks are moved back to their original position to save space.

Drive Mechanism:

Manual: A hand-crank system allows the user to move the racks by turning a crank. This method is more labor-intensive but cost-effective.

…

For more detailed information about the working principle of mobile compactors, please click here: https://www.cydfurniture.com/en/a/news/mobile-compactor-working-principle.html