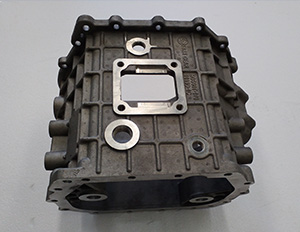

The lost foam casting process is suitable for a large number of castings that have intricate structural features and are difficult to produce by other methods. From the actual situation of developed countries, such as the United States and several European countries that have lost foam process operations, this view is true. Lost foam process has been successfully used to produce aluminum alloy engine blocks and has been mass-produced in the United States for automobiles and ships. This casting method has given a demonstration to the world’s foundry industry, proving the advantages of the lost foam process.

In China, the development of lost foam technology shows the advantages of this process from different aspects. And has been mostly applied to cast iron and cast steel products. It has been used to investing in the production of various parts, from relatively simple to parts with relatively complex features. In addition, it is also suitable for different production operations including mass production, loose parts, and even prototypes.

In order to ensure that the lost foam raw sand has sufficient fluidity to fill the complex deep cavity parts of the foam pattern, plus a thick coating layer has a certain mechanical strength to prevent box collapse, therefore the lost foam casting requires roundness Be good enough. In addition, during the casting of lost foam casting, a large amount of gas or liquid pyrolysis products will be generated along with the cracking and burning of the foam pattern. Therefore, the sand must have sufficient air permeability to prevent the residue from overflowing.

Since the ceramic casting sand is close to a spherical shape, it has good fluidity and high air permeability. It can fill slender holes, angled parts of castings and complex inner cavity parts, and it is easier to compact. Material, which guarantees its wide application in cast iron and cast steel (including high manganese steel, etc.).

The use of ceramic casting sand has the advantages of high fire resistance, good fluidity and high air permeability, and is used for lost foam casting, which can increase the yield of castings, reduce costs, and improve the working environment.

Physical and chemical properties of ceramic foundry sand

| Grain shape | spherical | Coefficient of expansion | (20~1000℃)6×10-6/℃ |

| Colour | Black-brown | Al2O3 | 65-85% |

| Refractory temperature | ≥ 1800 ℃ | Fe2O3 | ≤5% |

| Bulk Specific Gravity | 1.95 -2.05g /cm3 | SiO2 | 8~22% |

| True density | 3.4g /cm3 | TiO2 | 3~4.5% |

| Thermal conductivity | (1200 ℃)5.27W/M·K | PH value | 7~8 |

| Granularity | 6 ~ 320 mesh (φ0.053 ~ 3.36mm) | / | |