Sand casting refers to a casting method for producing castings in a sand mold. Because the molding materials used in sand casting are cheap and easy to obtain, the castings are easy to manufacture, and can be adapted to the single-piece production, batch production and mass production of castings. For a long time, it has been the basic process in casting production.

Sand-type raw materials are foundry sand and sand binder.

The foundry sand has enamel sand, zircon sand, chromite ore, corundum sand and the like.

The binder is used to make the sand mold and the core made of the shaped sand have a certain strength, and the loose sand particles are joined together. There are clays, drying oils, semi-drying oils, water-soluble silicates or phosphates and various synthetic resins.

1. Clay wet sand type: The main binder of clay is made of clay and appropriate amount of water. After being made into sand type, it is directly combined and poured in a wet state. The strength of the wet sand depends on the clay slurry in which the clay and water are mixed in a certain ratio. The amount of clay and moisture are important process factors for the wet type of clay.

Advantage:

(1) Clay is rich in resources and cheap.

(2) Most of the used clay wet sand can be recycled after proper sand treatment.

(3) The cycle for manufacturing the mold is short and the work efficiency is high.

(4) The mixed molding sand can be used for a long time.

(5) After sand compaction, it can still withstand a small amount of deformation without damage, which is very advantageous for both drafting and lower core.

Disadvantages:

(1) Applying a thick clay slurry to the surface of the sand during sand mixing requires high-power sand mixing equipment with a smashing effect, otherwise it is impossible to obtain a good quality sand.

(2) Since the sand is well mixed, it has a relatively high strength. The molding sand is not easy to flow during the molding, and it is difficult to compact. The manual molding is both laborious and requires a certain skill. When the machine is used, the equipment is complicated and huge.

(3) The rigidity of the mold is not high, and the dimensional accuracy of the casting is poor.

(4) Castings are prone to defects such as sand washing, sand inclusion, and porosity.

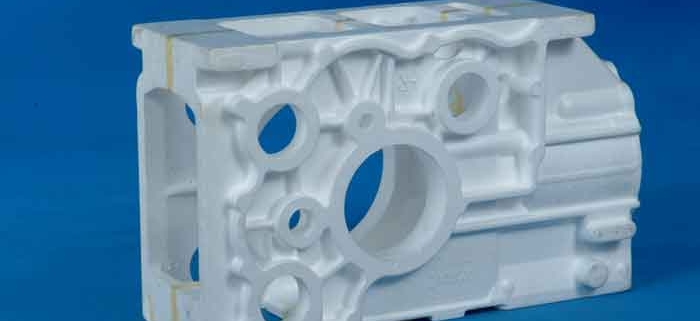

2. The mold used for sand casting is generally composed of an outer sand type and a core. In order to improve the surface quality of the casting, a layer of paint is often applied to the sand and core surfaces. The main components of the coating are powdery materials and binders with high refractoriness, high chemical stability, and a carrier (water or other solvent) and various additives for ease of application.

3. Clay dry sand type: The wet moisture of the molding sand used to make this sand type is slightly higher than that of the wet type. After the sand mold is prepared, the surface of the cavity should be coated with a refractory paint, and then dried in an oven. After it is cooled, it can be combined and cast.

Disadvantages: It takes a long time to dry the clay sand type, which consumes a lot of fuel, and the sand type is easily deformed during the drying process, which affects the accuracy of the casting. Clay dry sand types are commonly used in the manufacture of steel castings and larger cast iron parts.

4. Chemically hardened sand type: The sand used for this type of sand is called chemically hardened sand. The binder is generally a substance which can undergo molecular polymerization under the action of a hardener to form a three-dimensional structure, and various synthetic resins and water glass are commonly used.

There are basically three ways of chemical hardening.

(1) Self-hard

Both the binder and the hardener are added during the sand mixing. After being made into a sand mold or a core, the binder reacts under the action of the hardener to cause the sand mold or the core to harden by itself. The self-hardening method is mainly used for styling, but it is also used to manufacture larger cores or to produce cores with a small batch size.

(2) Aerosol hardening

Add binder and other auxiliary additives during sand mixing without first adding hardener. After molding or core-making, a gaseous hardener is blown or blown into the gaseous carrier to atomize the liquid hardener, which is dispersed in the sand or core, resulting in sand hardening. Aerosol hardening is mainly used for core making and sometimes for small sand types.

(3) Heat hardening

A binder and a latent hardener which does not function at normal temperature are added during sand mixing. After the sand or core is made, it is heated, at which time the latent hardener reacts with certain components of the binder to form an effective hardener that hardens the binder, thereby hardening the sand or core. The heat hardening method is mainly used for core making except for the production of a small thin shell sand type.

Sand casting is one of the casting processes, and the mold used for sand casting is generally composed of an outer sand type and a core. Because the molding materials used in sand casting are cheap and easy to obtain, the castings are easy to manufacture, and can be adapted to the single-piece production, batch production and mass production of castings. For a long time, it has been the basic process in casting production. At present, internationally, in all casting production, 60 to 70% of castings are produced in sand, and about 70% of them are produced using clay sand.