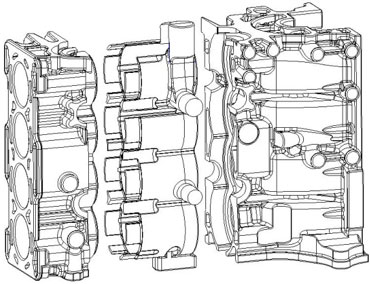

Large cylinder diameter wet diesel engine cylinder liner (≥φ125), usually used for single casting. According to the traditional mold design process, the produced blank is heavier, the casting cost is higher, and the machining allowance is large. Therefore, it is imperative to reduce the weight of the cast blank and thus reduce the machining allowance.

Before the improvement, the inner hole design of the mold, the traditional design is a diagonal line from the big end to the small end of the mold. This design makes the coating performance of the coating better, the cooling speed of the blank is uniform, and the big end and small end quality of the blank are produced. More uniform. However, due to the limited design, the slope is not too large (otherwise, the coating performance of the coating is poor, resulting in waste), so the processing margin of the produced blank is large.

After the improvement, there are three steps from the big end to the small end on the inner hole surface of the mold. Therefore, there are three steps in the outer round surface of the blank, which are substantially the same as the outer circular surface of the finished cylinder sleeve, so that the blank The machining allowance and weight are greatly reduced.

After the cylinder liner centrifugal casting mold was changed, we found two problems:

1. The wall thickness of the small end of the blank is reduced. When pouring, the cooling rate of the molten iron is accelerated, and the graphite form does not meet the standard requirements.

2. At the large end of the blank, due to the large step difference below the supporting shoulder, the speed of the molten iron in the solidification process is different, and it is easy to produce shrinkage on the inner hole surface of the blank.

Casting mold process adjustment:

Through the implementation of the second incubation process and the adjustment of the casting process, the qualified products are successfully produced. The second inoculation treatment process, before the pouring of molten iron, under certain conditions (such as a certain superheat temperature, a certain chemical composition, a suitable addition method, etc.), a certain amount of substance (referred to as an inoculant) is added to the molten iron. In order to change the solidification performance of the molten iron, improve the as-cast structure, and thereby achieve the purpose of improving the performance of the treatment method, said the inoculation treatment.

The purpose of the inoculation treatment is to promote graphitization, reduce the tendency of white mouth; improve the uniformity of the section; control the morphology of graphite, reduce the formation of D, E type symbiotic graphite and ferrite to obtain medium size A type graphite.

After the mold change is analyzed, the wall thickness of the small end of the blank is thinned, and the cooling rate of the molten iron is accelerated. During the solidification process, the degree of supercooling of the molten iron (0 T) is increased, and the transformation from ΔT1 to ΔT2 and ΔT3 causes the graphite structure to become smaller. It is tapered and transformed from type A graphite to type B, D, and E graphite. In addition, due to the long casting route, 12 sets of molten iron should be poured into 12 centrifugal casting machines, and the pouring time is relatively long. Obviously, a single inoculation process can no longer meet the quality requirements. A second inoculation process must be carried out, that is, an appropriate amount of inoculant is added to the small pouring bag before the centrifugal pouring machine. This treatment method, from the melting of the inoculant to the pouring time is very short, maximizes the role of inoculant, reduces the decline of pregnancy, in the actual production, the rational choice of the size and amount of inoculant is the key to success.

Adjustment of the casting process of the centrifugal casting machine to eliminate shrinkage:

The reason for the formation of the shrinkage is various, and the most fundamental reason is that when the molten iron in the shrinkage portion is solidified, the shrinkage is not obtained. After the casting mold structure is changed, the step of the large end of the blank supports the shoulder. Because the wall thickness of the blank differs greatly, the solidification speed of the molten iron is different, and the molten iron at the thin wall first solidifies, causing the molten iron at the thick wall after solidification to solidify. Feeding, forming a shrink.

Therefore, for the reasons of shrinkage formation, after repeated experiments, the following countermeasures are taken: increasing the rotational speed of the centrifugal casting machine (N); appropriately extending the rotation time of the centrifugal casting machine (TI); appropriately extending the molten iron from the small pouring bag to the pouring Machine pouring time (T2). Through calculation, it is found that there is a mathematical correspondence between (N) . ( T1 ) . ( T2 ) and the blank inner diameter (D). That is, the inner diameter (D) of the blank and the rotational speed (N) of the mold are proportional to each other; and the relationship between the rotation time (TI) of the mold and the casting time (T2). When the inner diameter of the blank is constant, if the actual rotation speed of the mold is lower than the theoretically required rotation speed of the mold corresponding to Fig. 8, shrinkage will occur; similarly, if the actual rotation time of the mold (T1), the pouring time (T2) is lower than the theoretically required rotation time (TI) of the mold corresponding to Fig. 8, and the shrinkage is also generated when the pouring time (T2).

Cost reduction:

The improved liner blank has a reduced wall thickness and a reduced weight, which saves the casting raw materials. At the same time, due to the reduction of machining allowance, the machining tool wear is reduced and the service life is prolonged. With an average weight loss of 3.6 per blank, the tool can save 0.02 yuan / piece. Since the improvement of the cylinder liner was put on the market, it has been more than a year since the production of a large cylinder bore diesel engine cylinder casing of about 50,000. The raw materials and tools saved a total of 614,000 yuan, reducing costs and improving economic efficiency.