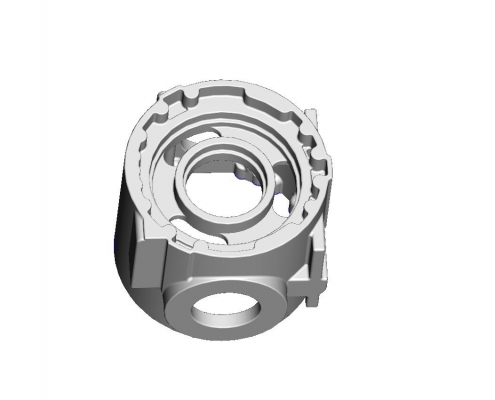

Gear box cover mold

In order to facilitate the mold release, a certain slope is left in the direction of the mold and the core mold to avoid damage to the sand or sand core. Since (JB/T5105-1991) found that the measured height h is 40-100mm, the draft angle of the metal pattern is set to 1.5 degrees. Since the height of the C950 gear box cover is 57mm, the draft angle is set to 1.5. degree.

1. Determine the parting surface

(1) Try to place all or most of the castings in the same half.

In order to ensure the dimensional accuracy of the castings, all or most of the castings should be placed in the same half, if

If it is not possible, the working surface of the casting and the processing reference surface should be placed in the same half.

(2) Minimize the parting surface

Reducing the number of parting surfaces is not only easy to guarantee the accuracy of the casting, but also requires less sand boxes.

(3) As far as possible, the parting surface should be flat.

The straight parting surface simplifies the molding process and the manufacturing work of the formwork, and it is easy to ensure the accuracy of the casting.

(4) Pay attention to reduce the height of the flask

In order to facilitate the mold release, the parting surface is generally selected on the largest section of the casting, but be careful not to make the pattern

The inside of the box is too high.

2. Basic principles of sand core design

Generally, the shape of the core is considered according to the size and structural characteristics of the casting and the specific production conditions.

The number and the box surface problem, the stress is to be achieved, the core box structure is simple and applicable, the core making and the lower core are easy to operate, and the inner cavity of the casting with dimensional accuracy can be ensured, so that the casting has no pores or other defects.

3. Vertical sand core

The C950 gearbox cover requires two vertical sand cores. Therefore, the main calculation of the vertical sand core is here.

Process. The C950 gearbox cover needs to make the upper and lower core heads, so that the sand core can be positioned accurately and the support is reliable, and the sand core is more suitable for the sand core with a height larger than the diameter. Since the cores of the two sand cores are not the same size, the upper and lower core heads of different heights are adopted.