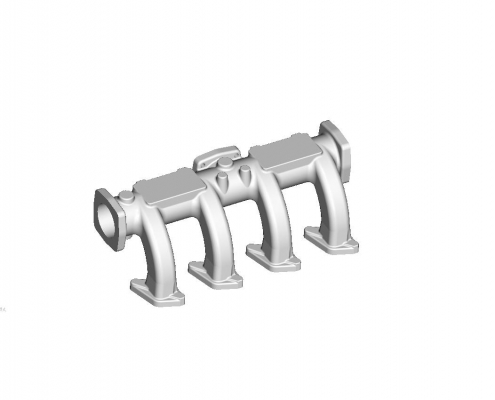

Intake pipe mould

The intake pipe is one of the most different structural components of the electronically controlled fuel injection engine and the carburetor engine. Since the EFI engine only has air flowing through the intake pipe, the dynamic effect (inertia effect and wave effect) of the intake pipe should be fully considered in order to improve the charging efficiency, and the intake air uniformity should be considered. The dynamic matching of the intake system with the engine allows the engine’s torque characteristics to be greatly improved over a wide range of speeds. In practical applications, there are intake pipes of a specific length designed according to the inertia effect and the wave effect at the specific speed region, and also have variable length intake pipes.

| Place of Origin: Henan, China (Mainland) | Brand Name: Liushi&OEM | Model Number: Customized |

| Product Name:Intake pipe mould | Material: Aluminum | Surface treatment: TEFLON surface coating |

| Service:

Customer’s Drawings |

Certification: ISO9001 | Dimensions: Customized Sizes |

| Application:

Machinery Parts |

Process: Lost Foam Casting | Lead Time: 45 Days |

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

|

Mould material

|

ZL106 aluminium casting alloy,7075 reflectal

|

|

Casting alloy

|

Cast aluminium,Cast steel,Grey iron,Ductile iron

|

|

Cavity qty

|

Single cavity, Multiple cavity, Unit cavity

|

|

Process

|

Adopts CNC, WEDM-LS, drill machine, polishing machines, lathe, milling machine,etc.

|

|

Treatment

|

TEFLON surface coating treatment and Heat treatment and etc

|

|

Design software

|

AutoCAD, UG, Pro-E, Solidworks, etc

|

|

Lead time

|

15to 30 days for samples, exact time depends on mold complexity

|

|

Forming machine

|

Cold chamber die-casting machineS180T/280T/500T/800T/1250T

Hot chamber die-casting machines58T/88T168T

|

|

Mold life

|

30000 to 50000 depend on products

|