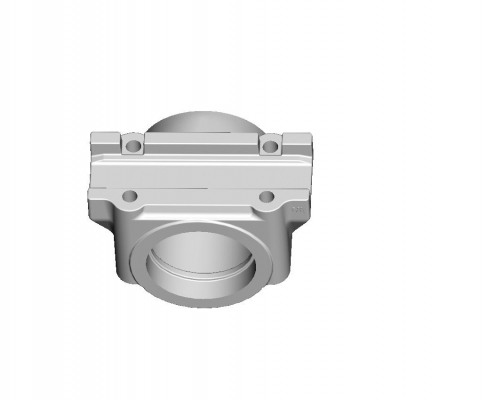

Balance shaft shell mold

The balance shaft shell mold has small volume and complicated shape, and the inner structure of the shaft shell part cannot have shrinkage holes, and there is no possibility of casting cracks. If sand casting is used, the process complexity requires multiple sand cores, and the casting dimensional accuracy is low. Due to the high dimensional accuracy of the lost foam castings, the surface is smooth, the internal defects are few, the process is simple, the cost is low, and large-scale mass production can be realized. Therefore, we have carried out the development of this type of castings for lost foam casting and achieved the expected results, which are currently in mass production.

Lost foam casting (also known as solid casting) is a solid molding of foam plastic mold using non-bonding agent dry sand combined with vacuuming technology. It is a combination of foam models similar in shape and shape of castings into a model cluster, brushed with refractory coating. After drying, it is buried in dry quartz sand for vibration modeling, pouring under negative pressure, gasifying the model, liquid metal occupying the position of the model, and forming a new casting method after solidification and cooling.

Compared with traditional casting technology, lost foam casting has the following characteristics: 1. Good casting quality and low cost; 2. Unlimited material and suitable size; 3, size 4, high precision, smooth surface, reduced cleaning, saving machine ; 5, internal defects are greatly reduced, the organization is dense; 6 can achieve large-scale, high-volume production. The automated assembly line is environmentally friendly. 7, can greatly improve the working environment, reduce labor intensity, reduce energy consumption.

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

|

Mould material

|

ZL106 aluminium casting alloy,7075 reflectal

|

|

Casting alloy

|

Cast aluminium,Cast steel,Grey iron,Ductile iron

|

|

Cavity qty

|

Single cavity, Multiple cavity, Unit cavity

|

|

Process

|

Adopts CNC, WEDM-LS, drill machine, polishing machines, lathe, milling machine,etc.

|

|

Treatment

|

TEFLON surface coating treatment and Heat treatment and etc

|

|

Design software

|

AutoCAD, UG, Pro-E, Solidworks, etc

|

|

Lead time

|

15to 30 days for samples, exact time depends on mold complexity

|

|

Forming machine

|

Cold chamber die-casting machineS180T/280T/500T/800T/1250T

Hot chamber die-casting machines58T/88T168T

|

|

Mold life

|

30000 to 50000 depend on products

|